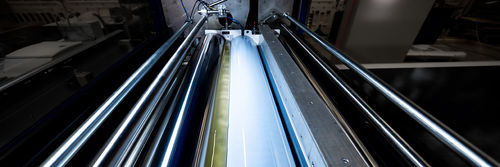

Roller coaters and curtain coating machines with technology from Venjakob|WO-TECH

Various coating methods can be used for the coating. The roller and curtain coating, without edge finishing, is used for flat components such as doors or, for example, panels made of various materials. In the case of rolling, the advantages lie in the resource-saving coating consumption due to the high application efficiency of 100 percent; in the case of curtain coating, in the possibility of apply higher coat thicknesses.

Everything from one source from the specialists for surface technology!

Venjakob also gives 100 percent when it comes to offering everything from one single source as a specialist for surface technology. The range includes a broad portfolio of spray coating systems as well as the suitable conveyor technology and handling systems.

In cooperation with our partner, WO-TECH GmbH, specialist for surface technology, with many years of know-how in rolling and curtain coating technology, we complement our product portfolio to our spraying machines as a further application method.

Combined processes for best surface results

Depending on requirements, roller and curtain coating coaters can be combined with other processes such as coating as well as surface pretreatment and drying in a well thought-out, user-oriented overall complete system solution. The best surface results are achieved through targeted surface and edge applications and an overall high coating performance.

Roller coating: Use and advantages

One-sided and double-sided coating of flat panels without profiling (e.g. MDF boards) can be carried out using the rolling process.