Centrifugal fan LFS seriesventilationlaboratorydirect-drive

Add to favorites

Compare this product

Characteristics

- Configuration

- centrifugal

- Function

- ventilation

- Applications

- laboratory

- Other characteristics

- direct-drive, with external rotor, low-pressure, with forward-curved blades

- Air flow

Min.: 148 m³/h

(5,226.571 ft³/h)Max.: 5,600 m³/h

(197,762.134 ft³/h)

Description

Application

The LFS fans are widely used in the installations that require precise metering of air and good resistance to various chemical agents. They are commonly used in ventilation systems of chemical storage cabinets or chemical laboratories.

They are also used in laboratory hoods, and for plastic processing and shrink wrapping.

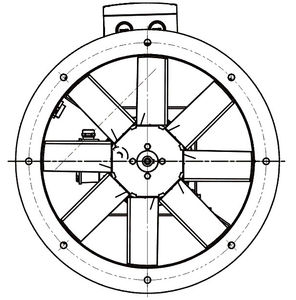

Construction

A radial, low-pressure, directly driven fan. The welded rotor, provided with forward-tilted blades is made of acid-resistant steel sheet. The rotor and the motor are dynamically balanced according to ISO IS01940 standard.

Housing made of stainless steel sheet is connected to the electric motor by a double temperature barrier consisting of a motor jointing sleeve and a disk of a high heat dispersing capability. The fan is designed for transporting air at temperatures of up to 150°C (the rotor made of galvanised steel sheet, version of the fan: G HT) or up to 200°C (the rotor made of acid-resistant steel sheet, version of the fan: AP HT).

LFS fans are manufactured in the LG90 configuration as standard. On request, the equipment can be supplied in any RD configuration.

Electric motor

The fans are provided with asynchronous, single-phase motors with capacitors 220-240V, 50Hz or three-phase 220-240/380-420V, with an external rotor and ball beraings, according to the standards IEC 72 and IEC 34-1; degree of protection IP 55 and winding insulation class F.

Catalogs

No catalogs are available for this product.

See all of Ventur‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.