Centrifugal fan LFB seriescoolingexhaustdrying

Add to favorites

Compare this product

Characteristics

- Configuration

- centrifugal

- Function

- cooling, exhaust, drying, ventilation

- Material

- galvanised steel

- Applications

- industrial

- Other characteristics

- direct-drive, low-pressure

- Air flow

Max.: 10,350 m³/h

(365,506.801 ft³/h)Min.: 2,100 m³/h

(74,160.8 ft³/h)

Description

Application

The LFB fans is designed for use in various mechanical ventilation systems. They are designed for ventilation of rooms where the level of dust is low. Exemplary applications comprise pressure and exhaust ventilation in individual ventilation and air conditioning systems.

They are commonly used in cooling and drying systems, local exhaust facilities, ventilation of shops in various industries, etc. They perform well in air filtration systems, e.g. in exhaust systems in paint shops, spray booths, etc.

Construction

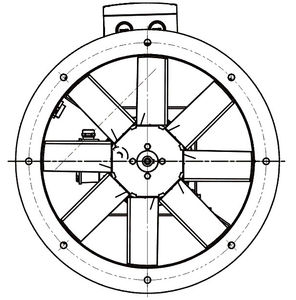

A radial, low-pressure, directly driven fan. The welded rotor, provided with forward-tilted blades is made of galvanized steel sheet. The rotors are dynamically balanced according to the standard ISO 1940. Housing is made of welded steel sheet, reinforced with steel angle bars and connected to the base of the electric motor.

The whole set is painted with powder paint. The fans are designed for transporting non-aggressive and non-explosive, dust-free gases. As a standard, the LFB fans are manufactured in a LG configuration with a protective mesh at the inlet.

On request, we can supply the equipment in any RD configuration and in any color from the RAL palette (RAL 5010 - blue is the standard color).

Electric motor

Asynchronous, three-phase 230/400V or 400V, 50Hz, or single-phase 230V, 50Hz, with a capacitor. The motors are manufactured in accordance with IEC 60072 and IEC 60034 standards, and have been awarded with a CE mark. Insulation class F, degree of protection IP 55.

Catalogs

No catalogs are available for this product.

See all of Ventur‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.