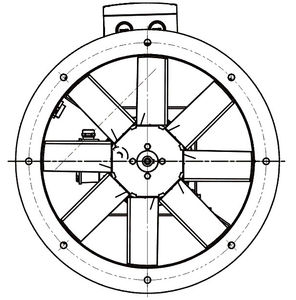

ATEX fan EGM series radialexhaustexplosion-proof

Add to favorites

Compare this product

Characteristics

- Type

- ATEX

- Configuration

- radial

- Function

- exhaust, explosion-proof

- Drive mechanism

- EC motor

- Material

- steel, aluminum

- Applications

- laboratory, for chemical applications

- Air flow

Min.: 1,030 m³/h

(36,374.107 ft³/h)Max.: 6,650 m³/h

(234,842.534 ft³/h)

Description

Application

For use in lacquer spraying booths, chemical laboratories, chemical industry, petroleum chemistry, etc. The radial EGM fans are manufactured in compliance with the international standard ISO 9001 and the standard PN-EN 13980.

Designed for use in potentially explosive environments, other than coal mines and dog headings.

Equipment meets requirements set for the group II, category 2G/3G - zone 1 and/or 2 (Z1 and/or Z2) and 2D – zone 21 and/or 22 (Z21 and/or Z22) or category 2G/D. Awarded with a CE mark and meets requirements of the ATEX Directive 94/9/EC.

Construction

Rotors of the EGM fans are made of aluminum alloys or welded from steel sheet. They are self-cleaning and covered with powder paint. All versions of EGM feature a rotor balanced according to ISO 1940-1.

Housing made of welded steel sheet, covered with powder paint (colour RAL 9005 – black). The housing is provided with inspection and drainage holes. To minimise the risk of sparking, some segments have been made of brazen sheet.

On request, we can supply rotors and housing made of galvanised, zinc-coated or stainless steel.

Electric motor

The fans are provided with electric induction three-phase motors (230/400V or 400V, 50Hz) and are adapted for operation within potentially explosive environments. On request, we can supply motors with a different temperature rating and various housing protection e.g., types nA, d, de.

Catalogs

No catalogs are available for this product.

See all of Ventur‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.