- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

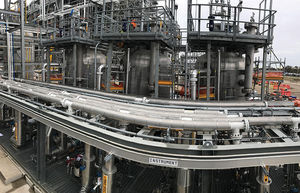

Wastewater treatment degreasing unit Agira™

Add to favorites

Compare this product

Characteristics

- Options

- wastewater treatment

Description

Agira™ consists of a hydrolysis tank and an aerobic bioreactor:

• The hydrolysis tank pre-treats the greasy matters in presence of lime before entering the bioreactor.

• The aerobic tank includes a patented foam cleaner and a dynamic mixer. This configuration enhances the biomass temperature (40-50°C) allowing high elimination efficiency in a reduced reactor footprint and low energy consumption.

The elimination efficiency of lipids reaches 70-90% depending on the grease quality and concentration.

Agira™ has a compact design and is perfectly adapted to degrade high loaded greasy effluents.

Treatment performances

• Total COD = 80 %

• TSS > 70 %

• Lipids > 90%

Operating conditions

• Applied charge : 3 to 5 kg HEM / m3.d

• 7,5 to 12,5 kg COD / m3.d

• Average retention time = 45 days

• COD / N/ P ratio applied : 200 / 2,5 / 0,75

• No recirculation from bioreactor to hydrolysis tank

• Energy consumption: 280 to 400 Wh / kg COD treated

Type

Two-stage intense aerobic process.

Applications

• Treatment of grease from municipal and agro-food industries wastewaters

• Cesspits content treatment

• Primary sludge stabilization

Catalogs

No catalogs are available for this product.

See all of VEOLIA WATER STI‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.