- Metrology - Laboratory

- Laboratory Equipment

- Water distillation unit

- VEOLIA WATER STI

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

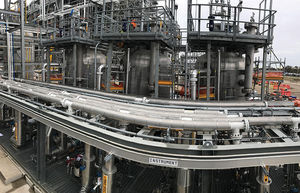

Water distillation unit Polaris™ 2.0for the pharmaceutical industry

Add to favorites

Compare this product

Characteristics

- Applications

- water, for the pharmaceutical industry

Description

The Polaris™ 2.0 product range features two systems, a skid-mounted multiple effect water distillator (MED) for the production of hot water for injection (WFI), and a skid-mounted pure steam generator (PSG) for the production of pure steam (PS). They guarantee WFI and PS quality in compliance with the European and U.S. Pharmacopoeia, and the produced PS is in line with the European sterilization standard EN285. The range also includes a new validated software for added peace of mind when ensuring compliance with the U.S. Food and Drug Administration (FDA) and Good Automated Manufacturing Practice 5 regulations.

Features two packaged distillation systems that reliably produce hot water for injection and pure steam. To give users peace of mind, they are designed according to European and U.S. Pharmacopoeia and European sterilization standard EN285, and feature validated software to ensure compliance.

At Veolia Water Technologies, we know the availability of pure fluids is crucial for the pharmaceutical and biotech industries when it comes to finished products manufacturing. To meet the needs of our customers, Polaris 2.0 has a robust design and thanks to easy and fast maintenance, it helps to minimize downtime and ensure the availability of high-quality WFI and PS when needed.

How does Polaris 2.0 work?

Harnessing the power of high pressure distillation and advanced droplet separation, the Polaris 2.0 range sets a new standard in water purification technology. To safeguard against microbiological contamination, cutting-edge sanitization features are seamlessly integrated into the system.

Catalogs

Polaris™ 2.0 PSG

4 Pages

Polaris™ 2.0 MED

4 Pages

Related Searches

- Liquid separator filter

- Pressure separator filter

- Filter for industrial applications

- Water separator filter

- Veolia water purification unit

- Automatic separator filter

- Reverse osmosis water purification unit

- Capsule filter

- Membrane filter

- Wastewater treatment filter

- Water distiller

- Process water purification unit

- Solid separator filter

- Compact water purification unit

- Potable water water purification unit

- Sand separator filter

- Industrial water purification unit

- Laboratory water purification unit

- PVC filter

- UV water purification unit

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.