The Alizair™ process avoid the propagation of odors and provide the operating agents with a healthy and safe environment.

In the sanitation network, the absence of air (and more precisely of oxygen) makes that wastewater become septic, and also malodorous. Gases are accumulated in the sewer headspace and emission to the open air can occur at the outlet in the treatment plant.

Wastewater and its by-product treatment (sludge, scum, etc.) also generate unpleasant smells.

The chemical species responsible of the olfactory nuisances are mainly Sulphide, Nitrogenous compounds and, sometimes, Volatile Organic Compounds (VOC).

The sulfide compounds mainly come from wastewater pretreatment, thickening and sludge dewatering stages. The nitrogenous compounds and the VOC are mainly from the sludge treatment.

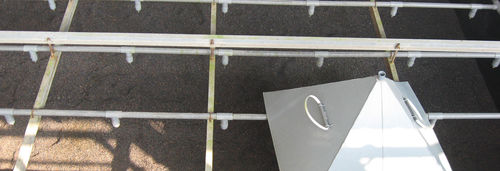

To avoid the propagation of odors and provide the operating agents with a healthy and safe environment, the works are put in negative pressure, the polluted air is collected and undergoes a deodorization treatment via the Alizair™ process.

Alizair™ is also available as compact units, ready to be used. There are four different sizes, with maximum flow ranging between 1800 and 6700 m³/h.

Features & Benefits

As it is biofiltration, Alizair™ is usually the least expensive odor removal solution and the easiest to operate.

Alizair™ oxidizes the malodorous substances (organic or inorganic) into inorganic and odorless compounds.

Alizair™ removes almost all the malodorous compounds. Its efficiency on mercaptans can be improved by the addition of downstream physical or chemical treatment.

Alizair™ requires low maintenance and reagent input.