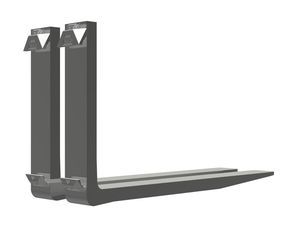

Agricultural pallet fork for forklift truckssteel

Add to favorites

Compare this product

Characteristics

- Type

- agricultural

- Product applications

- for forklift trucks

- Other characteristics

- steel

Description

Roller-guided forks are often used on high-capacity forklift trucks and in port logistics. The fork is guided on the fork carriage by rollers mounted on the fork. There are no standardized dimensions for the suspension of roller-guided forks. However, the VETTER database already contains a wide range of variants. Don’t hesitate to contact us!

Product benefits / Quality features

Optima heel

OptimaForkHeel: Up to three times the service life and a low level of deflection

Standard QualityForks by VETTER are delivered with the OptimaForkHeel with its additional wear zone to provide up to three times the service life, a low level of deflection and an optimum stress distribution.

Fork hook

High level of safety through tried-and-tested forks attachment

The attachment of the fork to the fork carriage is exceedingly important. After all, part of the load hangs directly on this, making it crucial for the operating reliability. No matter which type of attachment you require: All VETTER suspensions have been optimised with regard to their load-bearing capacity and weld design and thus guarantee the highest degree of safety.

Lateral pressing forks

Optimum use due to a high degree of dimensional accuracy and lateral pressing of flanks

VETTER forks stand out due to a high degree of dimensional accuracy and narrow tolerances. During the manufacturing process the flanks are pressed in a separate step to guarantee that they are ideal for the application and facilitate the use of accessories (e.g. fork extensions).

Tip alignment forks

High level of mutual compatibility due to identical fork tip heights

Every fork is individually straightened out to the same angle, generally 90°.

Catalogs

No catalogs are available for this product.

See all of VETTER GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.