- Products

- Catalogs

- News & Trends

- Exhibitions

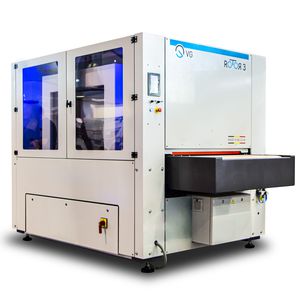

Edge rounding deburring machine CT 650finishinggrindingbelt

Add to favorites

Compare this product

Characteristics

- Associated function

- edge rounding, finishing, grinding

- Type

- belt

- Applications

- for sheet metal

Description

The essence of deburring, grinding, rounding and finishing. This deburring machine benefits from the VG basic features: reliable, practical and economical. Everything that VG Machines stands for. Made with an eye on finishing, fundamentally in the workshop.

The affordable CT 650 delivers metals up to 650 mm wide in their cleanest form. The controlled movement of the grinding belt ensures unprecedented reliability thanks to the electronic oscillation system. The integrated quick clamping system makes changing the grinding belt quick and easy. As a result, this economical machine offers you unrivalled finishing possibilities. This deburring machine is extremely suitable for deburring, rounding and finishing.

Applications

Slag removal

Deburring

Rounding edges

Oxide skin removal

Finish grinding

Oscillating brush system

The brush unit has 2 top brushes. 1 counterclockwise and 1 clockwise. The 2 stations, each with a large top brush, can move across the entire belt width. The setting of this stroke can be short or long. This allows both small and large cut parts to be deburred, rounded and finished perfectly. The brushes are easy to change and can be adjusted individually. Combinations of different types of brushes on 1 line can considerably shorten the production process in 1 pass.

Conveyor table

The CT 650 deburring machine is characterised by its consistent precision in the finish it delivers. To achieve this, the workpieces must be fed through the machine stably and consistently.

Related Searches

- Grinding machine

- Cylindrical grinding machine

- Automated grinding machine

- Deburring machine

- Finishing machine

- Metal sheet grinding machine

- Edge rounding deburring machine

- Brushing machine

- Finishing deburring machine

- Metal finishing machine

- Sheet metal deburring machine

- Grinding deburring machine

- Belt deburring machine

- Tube grinding machine

- Small workpiece grinding machine

- Metal profile grinding machine

- Stainless steel finishing machine

- Aluminum finishing machine

- Sheet metal finishing machine

- Grinding machine with brush

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.