- Products

- Catalogs

- News & Trends

- Exhibitions

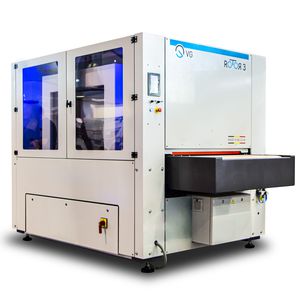

Cylindrical grinding machine C 150for metal sheetsfor tubesfor small workpieces

Add to favorites

Compare this product

Characteristics

- Type

- cylindrical

- Applications

- for metal sheets, for tubes, for small workpieces, metal profile

- Control type

- automatic

- Other characteristics

- with brush

Description

A wonderfull machine to process small components, rectangular tubes and flat metal bars. Suitable for a big range of materials: stainless steel, mild steels, aluminium, copper, brass and others.

The C150 has a grinding belt width of 150 mm.On the machine we have the VG adjusting system to keep the belt on track. We do not need an oscillating system.

This will result in a nice, clean and smooth grain finish.

A grinding belt change is quick and easy. In this way we can make a change from a deburring belt to a finishing belt.

A wide range of applications

Deburring, edge rounding, slag removal, grinding or graining. All these applications can be done on a wide range of materials. The component scan be cutted by a laser, plasma, waterjet or punched.

Top brush heads

The top brushes are mainly made for edge rounding. With one brush we already have a nice radius.

With 2 brushes we have a uniform radius. A nice radius on the outside and on the inside contour of a component.

The brushes are easily adjustable in height. This along the wear of the brushes. The required radius is also adjustable.

Cylindrical brush or barrel brush

As a last aggregate we can have a barrel brush. The purpose is to give a nice, smooth finish to the part. The brush that is commonly used fort his application is an abrasive non-woven brush.

These are also known as scotchbrite or falcon brush. As a result we get a nice, smooth and tight finish.

Holding small cutted components on the conveyor belt

We have 3 methods to hold small components on the conveyor belt:

Vacuum table: this is the most versatile way.

VIDEO

Related Searches

- Grinding machine

- Cylindrical grinding machine

- Automated grinding machine

- Deburring machine

- Finishing machine

- Metal sheet grinding machine

- Edge rounding deburring machine

- Brushing machine

- Finishing deburring machine

- Metal finishing machine

- Sheet metal deburring machine

- Tube grinding machine

- Belt deburring machine

- Grinding deburring machine

- Small workpiece grinding machine

- Metal profile grinding machine

- Stainless steel finishing machine

- Aluminum finishing machine

- Sheet metal finishing machine

- Grinding machine with brush

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.