- Products

- Catalogs

- News & Trends

- Exhibitions

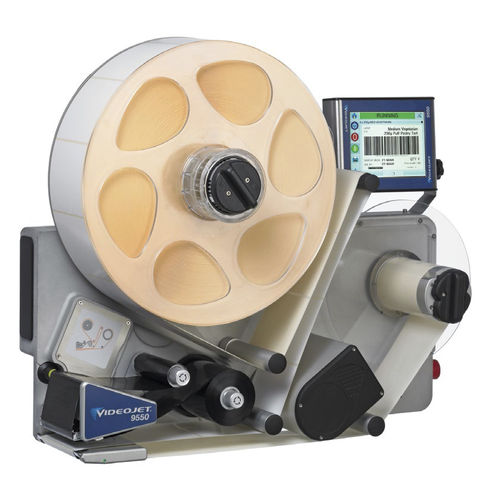

Thermal transfer label printer-applicator 9550for paperfor labelsmonochrome

Add to favorites

Compare this product

Characteristics

- Printing technology

- thermal transfer

- Applications

- for paper, for labels

- Number of colors

- monochrome

- Other characteristics

- automatic

- Printing speed

150 p/min

Description

Print & apply labeling solution for cartons, cases, pallets and shrinkwrap

The 9550 Label Printing Machine with Intelligent MotionTM is a smarter print and apply labeler that targets zero unscheduled downtime and reduces costs and errors in case coding operations. Automatic, precise control of the entire system together with Direct Apply label placement, provides the most efficient and reliable industrial labeling machine.

This Videojet print and apply labeling machine can aid with high contrast bar codes and other production information on various substrates like shrink and stretch wrap, cardboard boxes, egg cartons and cases.

In addition to the Videojet 9550 with Direct Apply™, Videojet offers 9550 units that feature a tamp applicator, a front-of-pack applicator or a corner-wrap applicator.

Alternatives to the Videojet 9550 print & apply labeler are Videojet large character marking systems like the Videojet 2361 and 2120 which enable the printing of expiration dates, lot/batch numbers, bar codes, and dates of manufacture directly on packaging on the production line.

Uptime Advantage keeps productivity up and costs down

• Zero mechanical adjustments during day-to-day operation

• Optimizes maintenance labor by eliminating more than 80% of wear parts

• Never miss a label, with self-adjusting label placement to accommodate varying line speeds, throughput and package sizes

• Improve throughput during build-back with Direct Apply labeling up to 150 packs per minute for typical 4”x6” labels

• Additional applicator models (Telescopic-Tamp, Front of Pack and Corner Wrap) to fit a range of applicatons

VIDEO

Catalogs

No catalogs are available for this product.

See all of VIDEOJET‘s catalogsRelated Searches

- Marking machine

- Automatic labelling machine

- Laser marking workstation

- Metal marking workstation

- Benchtop marking workstation

- Bottle labeling machine

- Printing machine

- Industrial printer

- Plastic marking workstation

- Label printer

- Thermal transfer label printer

- Industrial marking workstation

- High-speed marking machine

- Compact marking workstation

- Fiber laser marking machine

- Ink

- Labeller for the pharmaceutical industry

- Labeler for the cosmetics industry

- Top labelling machine

- Aluminum marking workstation

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.