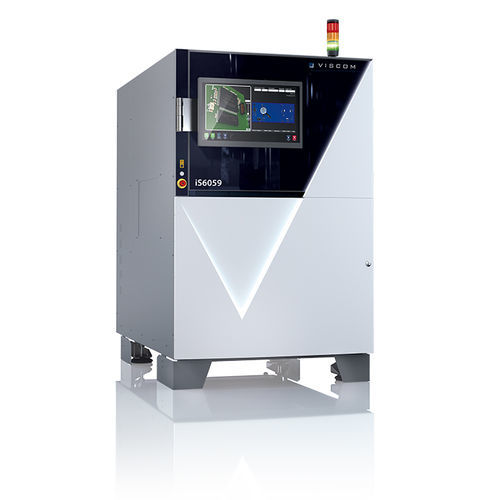

With innovative 3D camera technology, the iS6059 THT Inspection 3D AOI system inspects THT components, THT solder joints, press-fit and SMD components shadow-free and at high precision on the underside of the printed circuit board. PCBAs as well as inspection objects on workpiece carriers are inspected at high speed in 2D, 2½D and 3D. As a result, the iS6059 THT Inspection stands for maximum defect detection and highest throughput. Different lighting can be used flexibly and so provide inspection results in excellent quality.

• Maximum performance: Featuring a powerful 3D XM sensor system concept for performing quality inspections from below

• First-rate inspection quality: Shadow-free inspection thanks to 8 angled cameras

• System flexibility: reliable handling of a wide range of different inspection objects

• Optimum process design due to extended handling possibilities such as long board option

• Minimal time and training requirements thanks to Viscom standard software

• Flexible integration into existing productions

• Improved ergonomic design

CONNECTIVITY

• Global libraries, global calibration: Transferability to all systems

• Outstanding inspection program optimization thanks to flexible single and multiline verification solutions

• Simple operation and inspection program generation with EasyPro/vVision

• High-performance OCR software

• Connection via horizontal interfaces along the production line

• Viscom Quality Uplink: intelligent networking of Viscom inspection systems along the production line

• Production line control and product traceability