- Detection - Measurement

- Force Measurements

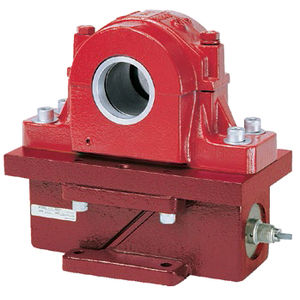

- Tension load cell

- Vishay Nobel Transducers

Bending beam force transducer GLTtensionstainless steel

Add to favorites

Compare this product

Characteristics

- Type

- tension, bending beam

- Other characteristics

- stainless steel

- Rated load

Min.: 20 lb

(9.07 kg)Max.: 500 lb

(226.8 kg)

Description

The BLH Nobel GLT transducers provide stable, accurate, and repeatable performance for low force web tension applications with a wide range of operating tensions, a small wrap angle, or a high roller weight to tension force ratio. Performance improves by 50% versus half bridge semiconductor type cells and drift is basically eliminated. Factory calibration, with closely matched output signals, eliminates field calibration and costly recalibration after the initial setup. Zero and span settings remain stable for tension forces operating at the low end of wide rangeability applications. Scribe marks allow for quick alignment of the GLT with the resultant tension force. Both frame (standard) and optional pillow block mounting configurations are available for dead shaft roller assemblies. GLT series transducers for low-force web tension applications use a differential bending beam transducer with a full Wheatstone bridge for excellent stability, temperature, and performance specifications. Transducers are constructed of stainless steel for durability in corrosive environments. Each unit can be rotated to measure the resultant tension force, not just a component of the force. The full bridge electrical output of each unit is calibrated within a tolerance of better than 0.25%. When coupled with BLH Nobel instrumentation, system calibration can be accomplished without using dead weights or other sources of known force. Zero and span settings also remain stable for tension forces operating at the low end of wide rangeability applications. Applications: Converting Equipment Winders/unwinders/rewinders Coaters/laminators Printing presses

Catalogs

Other Vishay Nobel Transducers products

Force Transducers & Tension Measurement Modules

Related Searches

- Force sensor

- Tension/compression force sensor

- Steel force transducer

- Strain gauge force transducer

- Stainless steel force sensor

- Weighing force sensor

- Stainless steel weighing scale

- Beam type force transducer

- Platform weighing scale

- Weighing terminal

- Compression force sensor

- Industrial weighing scale

- Waterproof weighing scale

- Digital weighing terminal

- IP67 force transducer

- Shear beam load cell

- IP65 force sensor

- Weighing scale with separate indicator

- Benchtop balance

- Compact force sensor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.