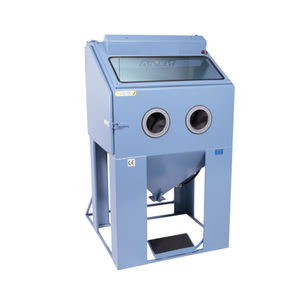

Suction blast cabinet VM30hand

Add to favorites

Compare this product

Characteristics

- Technology

- suction

- Operational mode

- hand

Description

The jetair range is designed to provide quick, clean and efficient results across a wide range of blast cleaning and treatment applications.

The VM30 features halogen lighting and a high performance cartridge dust collection/filtration system to ensure maximum internal visibility, vital for yielding first-class results.

A standard Jetair machine uses the suction feed method during the blasting process. Compressed air is used to create a ‘venturi’ effect, where blast air is sucked up through the hopper of the cabinet to the blast gun and then propelled onto the surface of the component. The media then falls back to the hopper and is recycled.

Alternatively, Jetair machines can use a pressure operated blast system which increases the speed of blasting by up to four times and increases efficiency. These pressure pots are available in large and small sizes and are an optional extra in the Jetair range.

Typical applications include:

Removal of paint, rust, scale, carbon and other similar deposits

Surface preparation prior to bonding, re-painting, re-coating or producing cosmetic finishes

Deburring or peening

Deflashing, cleaning and retexturing plastic moulds

Etching, decorating and engraving glass

Catalogs

No catalogs are available for this product.

See all of VIXEN‘s catalogsRelated Searches

- Automatic washing machine

- Water washing machine

- Industrial washing machine

- Stainless steel washing machine

- Ultrasonic cleaning system

- Process washing machine

- Blast machine

- Spray washing machine

- Metal shot blasting machine

- Parts washing machine

- Solvent washing machine

- Manual washing machine

- Blast room

- Compact washing machine

- Automotive washing machine

- Automatic blast machine

- Washing machine for the food industry

- Washing machine with rinsing

- Immersion cleaning system

- Hand blast cabinet

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.