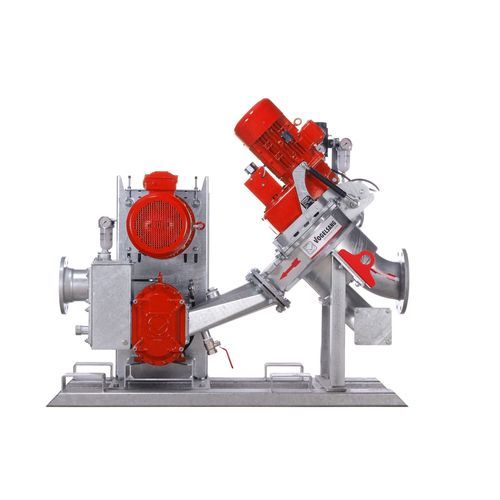

The BioCut is an efficient pump system for reliable and cost-effective pumping of heterogeneous media containing heavy material and disruptive matter. It consists of a self-priming rotary lobe pump from the VX series combined with a special type of construction of the tried-and-trusted wet grinder RotaCut – with both optimally coordinated and arranged to one another. The rotary lobe pump draws the medium – even out of a pit, if necessary – through the RotaCut. The RotaCut then separates out foreign matter (stones, metal parts etc.) due to their size or weight. During maintenance work, this foreign matter can then be removed through the cleaning port. Light solid matter and disruptive matter, such as fibers, wood etc., are drawn along in the flow of fluid to the cutting screen, where they are cutted and mixed with the fluid. This way, the pump system BioCut turns a heterogeneous fluid into a pumpable, homogeneous suspension. This suspension then reaches the rotary lobe pump on as short a route as possible.

When developing the BioCut pump system, we made sure to retain the full range of QuickService functions in the VX series rotary lobe pump and the RotaCut wet grinder: The RotaCut can be opened in a few simple steps, giving you free access to the cutting tools. Once the adjustment unit and the blade rotor have been dismounted, you can remove the cutting screen and, if necessary, renew the gasket. Replacing parts on the VX series rotary lobe pump is just as easy. When the cover is dismounted, you have free access to the pumping chamber and you can pull the rotary lobes off the shafts.