- Products

- Catalogs

- News & Trends

- Exhibitions

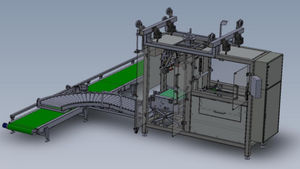

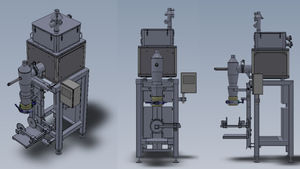

Vertical bagging machine VSFvacuumautomaticfor the food industry

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- vacuum

- Operational mode

- automatic

- Application domain

- for the food industry, for the chemical industry

- Throughput

Min.: 0 p/min

Max.: 10 p/min

Description

Fully automatic open mouth bagging machine for paper bags, with or without inliner, for free-flowing / heavy-flowing products, such as powdered milk, chemicals, animal feed, tea, charcoal. The machine can be equipped with different dosing and weighing modules depending on the product properties and the the capacity required. The bag closing can also differ. This machine can be combined with different sewing systems or bag sealers or a combination of the two. Many machine are equipped with sealing for an inner liner and double fold seal for an outer paper bag. The machine parameters are:

Execution

• free access underneath the filling spout

• filling space is separated from the transport through a wall

• closed housing to protect filling area

• machine doors made of sheet metal with windows, glass or polycarbonate doors

• bag placer with extended magazine

• bag spreading with servo-motoric positioning and integrated aspiration spout for displaced air

• different filling spouts with blow-up clamp or mechanical clamp.

• bag presser to minimise the air in the bag

Options

• housing made of stainless steel

• vibrators for product-guiding parts to avoid caking of the material

• vacuum probes for defluidisation of product

• vacuum chamber for entire bag

• top air removal with vacuum probe

• labelling or direct printing for bag-marking

• hygienic design for use in food industry industry

• integrated aspiration

• integrated check weigher

• integrated metal detector

• integrated metal separator

• integrated gross weigher calibratable according to EU-directive MID 2004/22/EC

• ATEX-conforming design

Other VOLLENDA-WERK GmbH products

Filling machines for bulk products / Open mouth fillers

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bottle filler

- Food product filling machine

- Bulk material bagging machine

- Bottle labeling machine

- Bagging machine for the food industry

- Volumetric filler

- Horizontal bagging machine

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Granulate bagging machine

- Container filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.