- Products

- Catalogs

- News & Trends

- Exhibitions

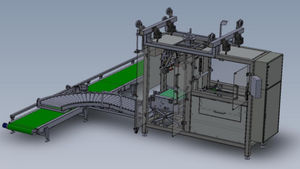

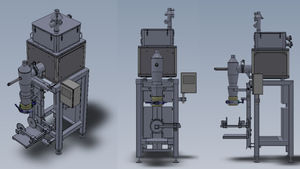

Vertical bagging machine VKKweightautomaticconstruction

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- weight

- Operational mode

- automatic

- Application domain

- construction, for the pharmaceutical industry

- Other characteristics

- compact

- Throughput

Max.: 26.7 p/min

Min.: 0 p/min

Description

This fully automatic bagging machine is for block-bottom bags. It is used for bagging construction material, spices, animal feed or flour that require a strong mechanical compaction. Bags are filled in a transport system that support the bags with its cassets from 3 sides. It transports the bags over a vibrator so that the product is compacted and the filling level in the bags is reduced substantially. In this manner the bags form compact and square packs. The filled bags are transported on a conveyor belt and led to a closing system which can be a sewing system a glueing- or sealing-machine.

The machine is executed with one or two filling spouts. It can be equipped with hopper weighers or with loss-in-weight weighing systems. The dosing system used depends on the product that is filled. The machine parameters are:

Execution

• closed housing of special section tube

• doors of metal sheet with windows, glass or polycarbonate

• components are easily accessible, easy to dismantle and to clean

• empty-bag magazine with storage option of up to 500 bags

• bag transport inside the machine in magazine and transport belt (bags do not drag on the ground)

• vibrator tracks (length is rated depending on product and capacity)

• format parts are quickly to replace without tools and suitable for various bag depths. Lateral guidings are adapted to the bag widths steplessly. (In many cases it is not even necessary to change formats when using different bag sizes!)

Options

• housing of stainless steel

• bag labeling system

• integrated metal detector and/or separator

• hygienic design for food and pharmaceutical application

• ATEX-conform design

Other VOLLENDA-WERK GmbH products

Filling machines for bulk products / Open mouth fillers

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bottle filler

- Food product filling machine

- Bulk material bagging machine

- Bottle labeling machine

- Bagging machine for the food industry

- Volumetric filler

- Horizontal bagging machine

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Granulate bagging machine

- Container filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.