- Products

- Catalogs

- News & Trends

- Exhibitions

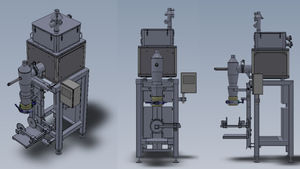

Vertical bagging machine VSFTform fill sealfor the chemical industryfor granulates

Add to favorites

Compare this product

Characteristics

- Type

- vertical

- Technology

- form fill seal

- Application domain

- for the chemical industry

- Product applications

- for granulates

- Throughput

Max.: 10 p/min

Min.: 0 p/min

Description

Fully automatic bagging and closing machine for plastic bags with or without gusset for plastic granules, chemical products, pesticides, sand, etc. The machines are very solid and can be equipped with various dosing systems and weighers (gross weighers, net weighers, loss-in-weight weighers).

Handling of product bag is a characteristic of this type of machine. The bag is always held and guided. After separation it is erected and then taken by a swivel arm with grabber. When arriving at the spout, the bag is openend and pulled flat after filling. During filling, the product in the bag is separated by a vibrator and compacted so that an optimum filling is guaranteed. From the spout the bag is transported to the bag closing device in an upright position and held by a pair of grabbers. After welding the bag is tilted and transported out of the housing lying down.

Execution

• machine frame whelded of carbon steel tubes

• polycarbonate or glass doors

• bag dispenser with bag drawer and pneumatic bag separation

• integrated bag sealing with impulse-heated or permanently-heated jaws

• roller conveyor with lifting table and motoric height adjustment for different bag sizes

• pneumatic bag beater

• very compact design

Options

• housing of stainless steel

• product guiding parts with different coatings

• bag-marking system

• movable execution

• cleaning device for bag sealing

• air removal from bag before sealing

• integrated gross weigher calibratable according to EU-directive MID 2004/22/EC

• ATEX-conform design

Other VOLLENDA-WERK GmbH products

Filling machines for bulk products / Open mouth fillers

Related Searches

- Automatic filler

- Bagging machine

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Automatic bagging machine

- FFS bagging machine

- Vertical bagging machine

- Bottle filler

- Food product filling machine

- Bulk material bagging machine

- Bottle labeling machine

- Bagging machine for the food industry

- Volumetric filler

- Horizontal bagging machine

- Filling system for the chemical industry

- Side labelling machine

- Filler for the pharmaceutical industry

- Granulate bagging machine

- Container filler

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.