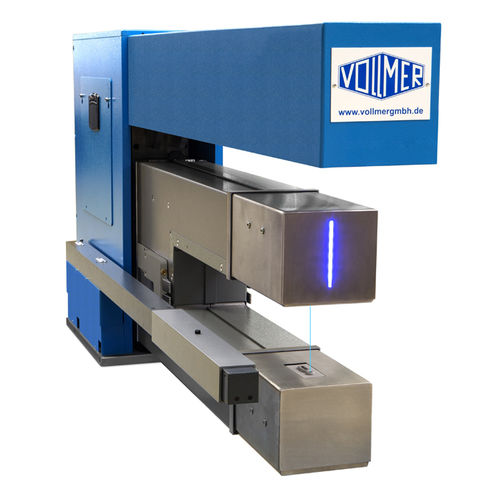

Strip thickness measuring machine VTLG seriesopticallaserhigh-precision

Add to favorites

Compare this product

Characteristics

- Measured physical value

- strip thickness

- Technology

- optical, laser

- Other characteristics

- high-precision

Description

With the new VTLG Series laser systems, Vollmer is giving strip thickness measurement new impetus: They combine the highest precision with rolling mill-oriented design. Thanks to their unique measuring method, they are suitable for use in cold rolling mills. With a measuring precision of ± 1 µm and scanning rate of up to 80 kHz, they offer the precision and speed necessary for the control of the strip thickness.

VTLG systems are the only laser gauges to measure the strip thickness during rolling in the mill, thus opening up completely new possibilities in production and quality assurance for our customers.

As with our contact gauges, they measure the thickness irrespective of the alloy – ideal preconditions for use in the rolling mill, but also on the annealing line, in the finishing section, on the strip edge miller or in the steel service centre.

Simple and safe

An automatic air cleaning system for the measuring window and beam path and the innovative temperature compensation ensure the highest precision even under difficult environmental conditions. VTLGs have fully automatic self-calibration with built-in gauge blocks, certified according to DAkkS. As the lasers conform to laser protection class 3B, no additional beam protection guards are necessary.

Catalogs

No catalogs are available for this product.

See all of VOLLMER‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- High-precision measuring machine

- Automatic measuring device

- Control measuring machine

- Laser measurement system

- Geometry measuring device

- Surface measuring machine

- Industrial profiler

- Thickness measurement system

- Direct-contact measuring machine

- Gauge measuring machine

- Diameter gauge

- Flatness measuring machine

- Strip measuring machine

- X-ray measurement system

- Wire measuring machine

- Film measurement system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.