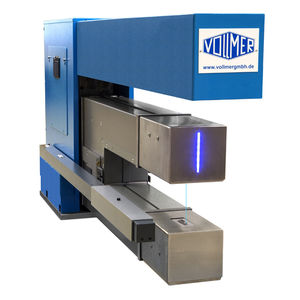

Gap sensor

Add to favorites

Compare this product

Description

Direct gap contol, predominantly for rolling of wedge-shaped strip and in tandem mills.

The heart of the system are two gap sensors which measure the gap width on the drive side and operator's side directly at the shaft of the work rolls, thus eliminating the attenuation of the measuring and adjustment signals caused by stand stretching, roll bearing clearance, etc. The thickness control system thus operates extremely quickly and directly.

Direct roll gap control effectively prevents wedge-shaped strip spreading to the side during rolling. In tandem mills it suppresses the lateral displacement of the strip caused by the high forces prevailing in the stand. The system is particularly effective during the rolling of thick strips: Strip leading and trailing ends are rolled out with high precision when using gap sensors.

Plate rolling mills achieve significantly improved results with direct gap measurement. Whether for strips or plates: The initial pass with gap sensors offers a significantly higher process reliability.

Catalogs

No catalogs are available for this product.

See all of VOLLMER‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.