Diameter measuring device VS seriesroundnesseccentricityautomatic

Add to favorites

Compare this product

Characteristics

- Measured value

- diameter, roundness, eccentricity

- Other characteristics

- automatic

Description

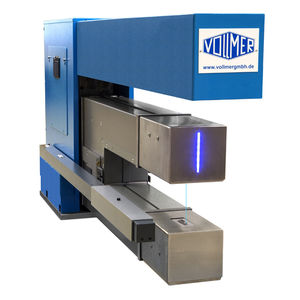

Roll measuring devices used either during grinding on the grinding machine or for offline measurement complete the Vollmer product spectrum for cold rolling.

Vollmer offers VSL/VSS systems for fully automatic roll measurement during dressing on the grinding machine, and traversable straddle gauges which are placed onto the roll for offline measurement.

VSL/VSS

The gauges from the VSL/VSS Series measure the form, diameter, roundness and eccentricity of the rolls during the grinding process with very high precision. Form, radial run-out and eccentricity are measures with a precision of ± 1 µm.

If an interface is available, they communicate online with the controller of the roll grinding machine and thus enable even more cost-effective use of the grinding machine.

With the appropriate configuration, they measure the height and lateral alignment of the roll in the grinding machine before grinding, often enabling the set-up time to be significantly reduced.

Vollmer produces the automatic roll measuring gauges for both bench-mounted machines where the roll is moved along the grinding wheel and for support machines where the grinding wheel is moved along the rotating roll. Vollmer supplies the systems for a broad spectrum of roll diameters.

Catalogs

No catalogs are available for this product.

See all of VOLLMER‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- High-precision measuring machine

- Automatic measuring device

- Control measuring machine

- Laser measurement system

- Geometry measuring device

- Surface measuring machine

- Industrial profiler

- Thickness measurement system

- Direct-contact measuring machine

- Gauge measuring machine

- Diameter gauge

- Flatness measuring machine

- Strip measuring machine

- X-ray measurement system

- Wire measuring machine

- Film measurement system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.