- Products

- Flat bottom extractor

- Vortex Global

- Products

- Catalogs

- News & Trends

- Exhibitions

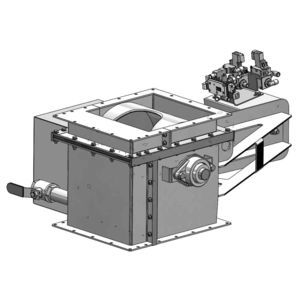

Flat bottom extractor Vortex® Aero Bin™

Add to favorites

Compare this product

Description

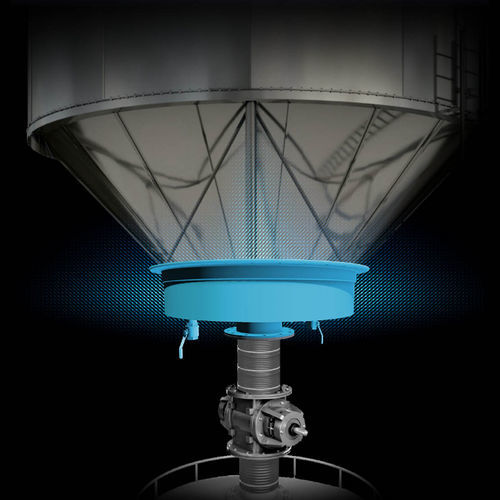

The Vortex® Aero Bin™ Bottom is attached to the bottom of flat- or conical-shaped silos and hoppers; in particular, storage silos with especially large diameter. It contains two main design features.

Ideal application: As materials begin to discharge through the silo output, a fan or blower injects low pressure, dry air (typically 6 psig | 41 kPa) upward into the silo via the aeration bed. As pneumatic pressures permeate the silo, the materials handled become fluidized. This encourages a consistent, continuous discharge of materials, in order to prevent bridging, rat holing and other discharge inefficiencies.

Key Features

Porous media is supported by a durable steel grate

Cleanout ports to inspect for product in the lower air chamber and maintain, if necessary. Each section of the conveyor has a cleanout port, located along the bottom of the lower air chamber

Rain ledge prevents precipitation from leaking into the conveyor

Inlet ports with ball valves to adjust the amount of air being injected into the air-gravity conveying system. Each section of the conveyor has inlet ports, located along the side of the lower air chamber

Several options for porous media material of construction, based on application and material characteristics

Viewports for in-line inspection. Each section of the conveyor has a viewport, located along the top of the upper chamber

Can have infinite length, depending on available head space

Simple installation and low maintenance requirements

No moving parts –for operator safety, reduced wear and prolonged service life

Low energy consumption using a single power source (electricity to power the fan or blower, no plant air required)

Catalogs

No catalogs are available for this product.

See all of Vortex Global‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.