- Industrial machines and equipment

- Heat Exchanger and Refrigeration

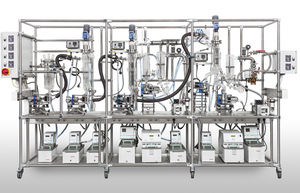

- Wiped film evaporator

- VTA Verfahrenstechnische Anlagen GmbH & Co. KG

Rotary evaporator VD seriesthin-filmwiped filmprocess

Add to favorites

Compare this product

Characteristics

- Type

- rotary, thin-film, wiped film

- Laboratory/process

- process

- Applications

- for liquids

- Other characteristics

- automatic, for large volumes

Description

WIPED FILM AND THIN FILM EVAPORATORS

High evaporation rates within a single process path

Wiped film and thin film evaporators consist of a cylindrical heating jacket and an inner rotating wiper system, distributing the product on the heating jacket as a thin and turbulent film. The turbulence in the wiped film increases the heat and mass transfer to achieve a high evaporation rate at short residence times, often within a single processing pass. The separated vapors are either condensed on an external condenser or further separated in a fractional column. Wiped film and thin film evaporation allow the handling of heat-sensitive, fouling and viscous products.

Performance features

• Capacity: 0,1 kg/h up to several t/h

• Operating pressure: full vacuum to overpressure

• Turn down ratio: 95 % and higher

• Visosity: 75.000 mPas or more at operating temperature

• Residence time: less than one minute

• Treatment of fouling products possible

• Combination for fractionation column: possible

Typical Applications

Processing of thermal sensitive or viscous products such as

• BDO butanediol

• Lecithin

• Whey

• Biopolymers

• Used oil

• Isocyanates TDI, HDI

• Devolatilization of silicone oil

Design features

• Available scales: laboratory, pilot and industrial

• Material of construction: glass, stainless steel, special alloys, glass lined

• GMP and hygienic version: available

• Shell and rotor: straight or tapered

• Heat exchange surface: 0,04 m² - 103 m²

• Various rotor types available

Catalogs

No catalogs are available for this product.

See all of VTA Verfahrenstechnische Anlagen GmbH & Co. KG‘s catalogsOther VTA Verfahrenstechnische Anlagen GmbH & Co. KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.