- Industrial machines and equipment

- Heat Exchanger and Refrigeration

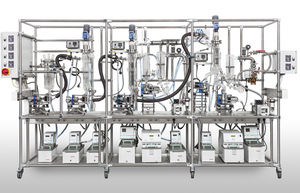

- Thermal evaporator

- VTA Verfahrenstechnische Anlagen GmbH & Co. KG

Thermal evaporator VK seriesshort pathprocessfor liquids

Add to favorites

Compare this product

Characteristics

- Type

- thermal, short path

- Laboratory/process

- process

- Applications

- for liquids

Description

SHORT PATH EVAPORATORS

Lowest distillation pressure for high boiling and thermal sensitive products

Short path - or molecular - distillation allows the evaporation of heat sensitive products at operating pressures down to 0,001 mbar at short residence times. On a cylindrical heating jacket the product is distributed and turbulized by a wiping system. The evaporated fraction is condensed on a condenser installed in the center of the evaporator. This arrangement minimizes the path from evaporation to condensing surface and achieves the lowest possible pressure drop. The high vacuum and the short residence time avoids thermal stress and decomposition of the processed products.

Performance features

• Capacity: 0,1 kg/h up to several t/h

• Operating pressure: min. 0,001 mbar

• Evaporation ratio: max. 95%

• Residence time: short, to minimise thermal degradation

• Viscosity: max. 20.000 mPas

• Melting points: max. 200°C

• Distillation process: fully continuous

Typical Applications

Fine vacuum distillation of thermal sensitive products such as

• PE wax

• 3 MCPD, GE, MOSH, MOAH removal from vegetable oils

• Monoglyceride concentration

• Used oil recovery

• Removal of POP's from fish oils

• EPA and DHA concentration

• Epoxy resins

• Lanolin alcohols, lanolin

• Isocyanates TDI, MDI, XDI, HDI

• Devolatilization of silicone oil

Design features

• Heat exchange surface: 0,04 m² - 80 m²

• Available scales: Laboratory, pilot and industrial

• Material of construction: glass, stainless steel, special alloys, glass lined

• Wiping systems: able to limit fouling

• Operating temperatures: max. 400°C

• ATEX and GMP design possible

Other VTA Verfahrenstechnische Anlagen GmbH & Co. KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.