- Production Machines

- Other Manufacturing Equipment

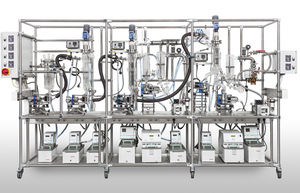

- Crude oil distillation plant

- VTA Verfahrenstechnische Anlagen GmbH & Co. KG

Crude oil distillation plant V series

Add to favorites

Compare this product

Characteristics

- Options

- for crude oil

Description

PILOT UNITS

Process development and production

Pilot units are the intermediate link between laboratory and industrial scale distillation units. The main aim of pilot scale distillations is to generate data for scale-up and process development. Moreover our pilot systems can be used for production of small product quantities as well. Experience, gained by experiments with a variety of products on our own pilot plants, has influenced the design and continuously improves the quality and performance of our systems.

Why pilot units?

• Verification of the results of the laboratory tests under real process conditions

• Determination of design parameters for a future industrial scale distillation system

• Scale-up for process equipment and aggregates of the industrial plant

• Monitoring of product properties during distillation (color, foaming, fouling etc.)

• Production of samples up to several metric tons

• Required raw material quantities about 20 - 400 kg

• MOC of evaporator: stainless steel

Performance features

• Capacity: 3 kg/h up to 100 kg/h

• Evaporator size: 0,06 m² - 0,5 m²

• Heating temperature: max. 350 °C (by thermal oil) - inductive heating for higher temperatures on request

• Operating pressure:

- min. 0,1 mbara for Wiped Film Evaporator

- min. 0,001 mbara for Short Path Evaporator

• Material of construction: stainless steel and special materials

• Low product hold up in pipes and vessels

Standard Set-up

1. Feed buffering vessel

2. Degassing stage

3. Short Path Evaporator

4. Cold traps

5. Vacuum system

6. Discharge systems

7. Heating and cooling systems

8. Control system

Other VTA Verfahrenstechnische Anlagen GmbH & Co. KG products

PRODUCTS

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.