- Industrial machines and equipment

- Heat Exchanger and Refrigeration

- Wiped film evaporator

- VTA Verfahrenstechnische Anlagen GmbH & Co. KG

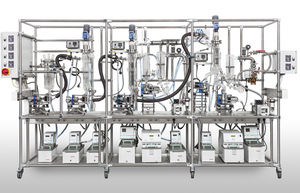

Thin-film evaporator V serieswiped filmshort pathprocess

Add to favorites

Compare this product

Characteristics

- Type

- thin-film, wiped film, short path

- Laboratory/process

- process

- Applications

- for liquids, acid

Description

GLASS LINED

THIN FILM & SHORT PATH EVAPORATORS

Processing of corrosive or metal active products

Highly corrosive products require special Cr-Ni base alloys or special construction materials such as titanium or tantalum for product wetted parts. On the other hand, some products are metal-active and do not allow metal contact. For processing heat-sensitive products at high vacuum and short residence times, VTA offers wiped film and short path evaporation technology with product contacting parts made of enamel (glass lined) and PTFE material. Often this is more economical than other special materials. Exceptions are hydrofluoric acid, compounds generating HF during the evaporation process and highly concentrated acids at high temperatures.

Performance features

• Capacity: 10 kg/h up to several 1.000 kg/h

• Operating pressure: full vacuum to overpressure

• Maximum heating temperature: 200 °C

• Heating media: Steam or hot oil

• Viscosity: max. 1.000 mPas at operating temperature

• Residence time: adjustable

Typical Applications

• Fatty acid chlorides

• Agressive agrochemicals

• Chloride acetic acid

• Chlorobenzol

• Phosphoroxychloride

Design features

• Evaporator types: Wiped film and short path

• Availalble scale: Pilot and industrial

• Alternative small scale: Borosilicate glass with PTFE rotor

• Heat exchange surface: 0,15 m² - 12 m²

• Packate unit distillation plants available

Catalogs

No catalogs are available for this product.

See all of VTA Verfahrenstechnische Anlagen GmbH & Co. KG‘s catalogsOther VTA Verfahrenstechnische Anlagen GmbH & Co. KG products

PRODUCTS

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.