- Environment - Health - Safety

- Waste Treatment

- Bottle perforator

- Wagner Maschinenbau GmbH

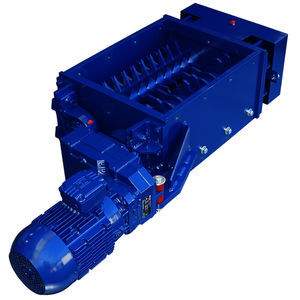

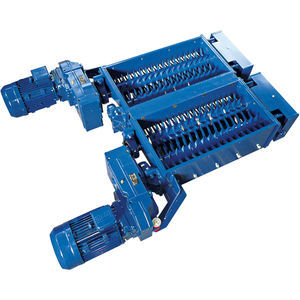

Bottle perforator Perforator 16-2

Add to favorites

Compare this product

Description

Perforators are used for slitting or piercing PET bottles or containers with 2.5 litres at full capacity. This process enables the production of compressed bales with higher density and compactness. There are three construction models available that achieve a throughput ranging from 450 to 2,400 kg per hour.

Operating mode:

The PET bottles drop continuously onto the two shafts equipped with wipers which move in opposite directions; these are equipped with easily exchangeable slitting tools. Then the bottles are absorbed and pierced. The bottles are pushed downwards by the shafts and subsequently positioned into the designated container or carried to the press.

100%

100% pierced bottles

Reliable

high availability and longevity

Low maintenance

low and simple maintenance

Modular design

adjustable to the customer's individual situation

Equipment

Control system

emergency-stop-device

selector switch, automatic/manual

Slitting tools

various tools made of hardox are available, multi-usage because they can be resharpened

the tools are applied to a shaft, each of them is individually exchangeable

the machine, being constructed in a segment system, is bolted together which allows for quick and easy tool exchange

Catalogs

No catalogs are available for this product.

See all of Wagner Maschinenbau GmbH‘s catalogsRelated Searches

- Grinding mill

- Waste shredding machine

- Single-shaft shredding machine

- Vertical grinding mill

- Primary shredding machine

- Wood shredding machine

- Two-shaft shredder

- Metal shredding machine

- Rotor lump breaker

- Paper shredding machine

- Plastic shredding machine

- Rugged shredding machine

- Cardboard shredder

- Waste lump breaker

- Compact shredding machine

- Energy-efficient shredder

- Recycling grinding mill

- Medical waste shredding machine

- Fabric shredder

- Heavy-duty shredder

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.