- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

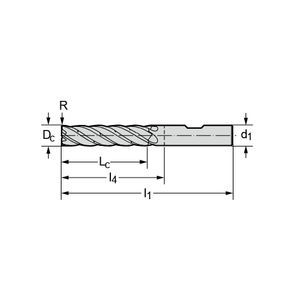

Shell-end milling cutter M5137 seriesindexable insertfinishingshoulder

Add to favorites

Compare this product

Characteristics

- Geometry

- shell-end

- Construction

- indexable insert

- Type

- finishing, shoulder

- Other characteristics

- cutting edge, 90° helix angle, cutting

- Diameter

Max.: 101.6 mm

(4 in)Min.: 25 mm

(0.98 in)

Description

Areas of application: General mechanical engineering, aerospace, medical, electronics and precision mechanical industries

Face milling, shoulder milling, ramping, pocket milling and circular interpolation milling

Primary application: Steel and cast iron; secondary application: Stainless steels and materials with difficult cutting properties

Inserts

Easy-cutting geometry

Indexable inserts with fully sintered circumference for maximum cost-efficiency (TNMU…)

Design with secondary cutting edge

The tool

90° approach angle

Interfaces: Weldon shank and bore adaption

Two depths of cut ap max = 5 or 8 mm

Two pitches for different applications

Shoulder milling cutter with triangular, double-sided indexable inserts

Benefits for you

High process reliability due to stable, double-sided indexable inserts

High level of cost-efficiency due to Tiger·tec® cutting tool materials and six cutting edges per indexable insert

Simple tool selection and low cutting tool material costs

Extended application range due to different corner radii of the TNMU indexable inserts

Catalogs

The right time for innovation.

44 Pages

Metal is our whole world

36 Pages

Related Searches

- Walter milling cutter

- Walter solid milling cutter

- Walter drill bit

- Walter steel milling cutter

- Walter clamping milling cutter

- Walter solid drill bit

- Walter metal milling cutter

- Walter milling cutter with cylindrical shank

- Walter insert milling cutter

- End mill milling tool

- Walter coated milling cutter

- Walter cast iron milling cutter

- Walter cutting insert

- Walter multi-purpose drill bit

- Walter cutting milling cutter

- Walter ball nose milling cutter

- Walter solid carbide milling cutter

- Walter face milling cutter

- Walter carbide drill bit

- Walter roughing milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.