- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Indexable insert milling cutter M5468 seriesroughingcopyingfor stainless steel

Add to favorites

Compare this product

Characteristics

- Construction

- indexable insert

- Type

- roughing, copying

- Treated material

- for stainless steel, for cast iron, for titanium alloys

- Other characteristics

- high-precision

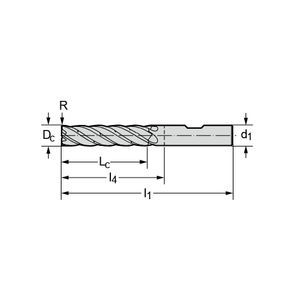

- Diameter

Max.: 125 mm

(4.92 in)Min.: 10 mm

(0.39 in)- Length

Max.: 119 mm

(4.69 in)Min.: 19 mm

(0.75 in)

Description

Universal system for copy milling, face milling, ramping, pocket milling and circular interpolation milling

Ideal for copy milling with minimal material removal

For steel, stainless steels, cast iron, non-ferrous metals, materials with difficult cutting properties and for hard machining

Areas of application: General mechanical engineering, aerospace, medical, electronics and precision mechanical industries

Inserts

Up to eight cutting edges with positive basic shape

Seven indexable insert sizes: RD.X0501M0; RD.X07T1M0; RO.X0803M04; RO.X10T3M08; RO.X1204M08; RO.X1605M08; RO.X2006M08

Fully sintered circumference (RDM…/ROM..)

Fully ground circumference (ROG.., RDH…/ROH..)

The tool

Xtra·tec® XT M5468 button insert milling cutter

No assembly parts getting in the way

Good chip removal when machining deep pockets

Benefits for you

Maximum productivity due to optimum cutting data and tool life

Maximum process reliability due to indexing of the indexable inserts using facets

Perfectly adapted to the machining operation due to different indexable insert sizes and geometries

High level of flexibility for use in existing adaptor systems due to cylindrical-modular interface

High level of cost-efficiency due to Tiger·tec® cutting tool materials, higher number of teeth

Lower tool costs and minimised effort thanks to universal usability

VIDEO

Catalogs

No catalogs are available for this product.

See all of Walter Tools‘s catalogsRelated Searches

- Walter milling cutter

- Walter solid milling cutter

- Walter drill bit

- Walter steel milling cutter

- Walter clamping milling cutter

- Walter solid drill bit

- Walter metal milling cutter

- Walter milling cutter with cylindrical shank

- Walter insert milling cutter

- End mill milling tool

- Walter coated milling cutter

- Walter cast iron milling cutter

- Walter cutting insert

- Walter multi-purpose drill bit

- Walter cutting milling cutter

- Walter ball nose milling cutter

- Walter solid carbide milling cutter

- Walter face milling cutter

- Walter carbide drill bit

- Walter roughing milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.