- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

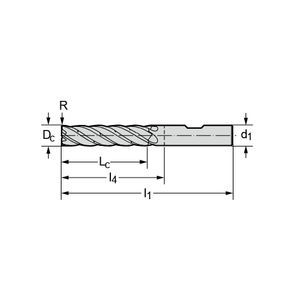

Solid carbide milling cutter MP060 seriesroughingfinishingPCD

Add to favorites

Compare this product

Characteristics

- Construction

- solid carbide

- Type

- roughing, finishing

- Material

- PCD

- Treated material

- for cast aluminum

- Other characteristics

- with internal coolant, for high-speed cutting, for molds

- Diameter

Max.: 125 mm

(4.92 in)Min.: 40 mm

(1.57 in)- Length

40 mm, 50 mm, 63 mm

(1.57 in, 1.97 in, 2.48 in)

Description

Non-ferrous metals (e.g. aluminium, Al-Si alloys, magnesium and magnesium-based alloys), as well as plastics and fibre-reinforced plastics

Areas of use: Automotive industry, aerospace industry, general mechanical engineering

Milling operations with the highest surface quality

For applications with emulsion or with MQL

The tool

MP060 face milling cutter with maximum number of teeth; dia. 40–125 mm

Benefits for you

Cost-effective, precise machining

Tool life increased by 20 to 200 times (compared to conventional solid carbide tools on the market)

Reduced cutting forces and minimal vibration tendency due to optimised geometries

Low cutting tool material costs due to extremely long tool life

Possibility of reconditioning and/or reconfiguration

VIDEO

Catalogs

No catalogs are available for this product.

See all of Walter Tools‘s catalogsRelated Searches

- Walter milling cutter

- Walter solid milling cutter

- Walter drill bit

- Walter steel milling cutter

- Walter clamping milling cutter

- Walter solid drill bit

- Walter metal milling cutter

- Walter milling cutter with cylindrical shank

- Walter insert milling cutter

- End mill milling tool

- Walter coated milling cutter

- Walter cast iron milling cutter

- Walter cutting insert

- Walter multi-purpose drill bit

- Walter cutting milling cutter

- Walter ball nose milling cutter

- Walter solid carbide milling cutter

- Walter face milling cutter

- Walter carbide drill bit

- Walter roughing milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.