- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

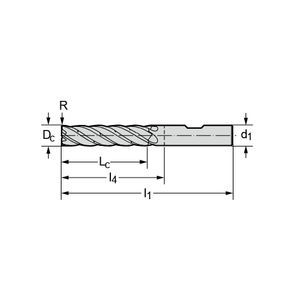

Solid carbide milling cutter MD025 series

Add to favorites

Compare this product

Characteristics

- Construction

- solid carbide

- Diameter

Max.: 16 mm

(0.63 in)Min.: 6 mm

(0.24 in)

Description

Near-net roughing with high feeds per tooth at low depth of cut

Machining operations for pocket, groove and freeform surfaces

ISO material groups P or M and S

Areas of use: Mould and die making, medical technology, aerospace and energy industries

The tool

Short, stable peripheral cutting edge

High number of teeth and reduced neck

Solid carbide milling cutter with high-feed face geometry

Large face radius Rf

High-feed milling at the highest level

Benefits for you

High process reliability thanks to low radial load on the tool

High-feed tools with even more teeth for maximum productivity

Ideal for variable use on complex components thanks to compact design and reduced neck for deep cavities

Catalogs

No catalogs are available for this product.

See all of Walter Tools‘s catalogsRelated Searches

- Walter milling cutter

- Walter solid milling cutter

- Walter drill bit

- Walter steel milling cutter

- Walter clamping milling cutter

- Walter solid drill bit

- Walter metal milling cutter

- Walter milling cutter with cylindrical shank

- Walter insert milling cutter

- End mill milling tool

- Walter coated milling cutter

- Walter cast iron milling cutter

- Walter cutting insert

- Walter multi-purpose drill bit

- Walter cutting milling cutter

- Walter ball nose milling cutter

- Walter solid carbide milling cutter

- Walter face milling cutter

- Walter carbide drill bit

- Walter roughing milling cutter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.