- Industrial machines and equipment

- Welding and Assembly

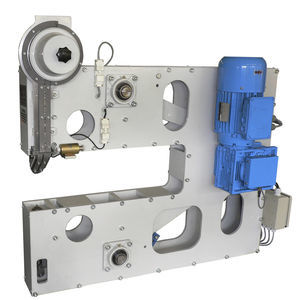

- Pneumatic riveting machine

- Walter Winter Verbindungstechnik GmbH & Co.KG

Push button riveting machine 090_20pneumaticautomaticautomatic feed

Add to favorites

Compare this product

Characteristics

- Operation

- pneumatic

- Other characteristics

- automatic, automatic feed, compact, push button

Description

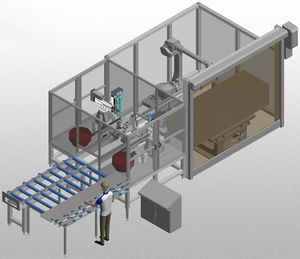

Pneumatic push button machine with ball part feed for automatic insertion. The ball parts are fed automatically and brought into position by a steel belt pusher. The push button top parts are also automatically fed and automatically inserted together with the ball parts. Depending on the material thickness, the pressure can be adjusted. Electronic push button top and ball part sensing for level control in the feed rail. A hopper system can hold up to 60.000 parts, which then automatically fill the sorting drums. The push button machine is installed in an industrial line.

Technical data:

Valve terminal with PLC-control

Sorting drum drive: Electrically with minimum and maximum control

Ball part feed: Pneumatic

Performance: 60 cycles/minute

Drive: Compact cylinder

Sorting drive: Small gear motor

Weight: Approx. 50 kg

Space requirement: 350 x 950 x 750 mm

Air pressure: Approx. 6 bar

Projection: 200 mm freely projecting

Application examples:

Medical technology, automotive industry, textile industry, clothing industry, packaging industry, folder production, etc.

VIDEO

Other Walter Winter Verbindungstechnik GmbH & Co.KG products

Special machines

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.