Fatigue testing machine manualmaterialfor the automotive industry

Add to favorites

Compare this product

Characteristics

- Test type

- fatigue

- Operating mode

- manual

- Test material

- material

- Sector

- for the automotive industry, for research and development, for the aeronautical industry

- Other characteristics

- LCF

Description

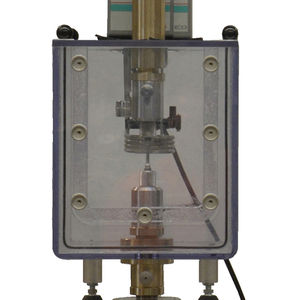

Low-Cylce Test for Fatigue (LCF)

Low Cycle Fatigue (LCF) testing provides important information for the design of industrial products in particular for the aerospace, automotive and power generation industries.

It is specific important for situations in which components or portions of components undergo either mechanically or thermally induced cyclic plastic strains that cause failure within relatively few (that is, approximately <105) cycles. Information obtained from strain-controlled fatigue testing may be an important element in the establishment of design criteria to protect against component failure by fatigue. Low Cycle Fatigue data are also useful in the areas of materials research and development, process and quality control, product performance, and failure analysis.

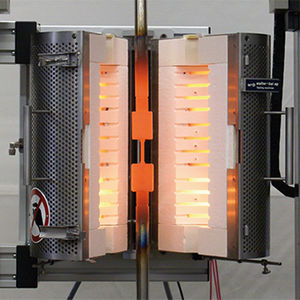

Low Cycle Fatigue Tests are normally run in strain control mode with the load as a dependent variable. ASTM E606 and ISO 12016 specify the standard practice for strain controlled LCF Testing simulating the mechanical loading into the plastic region. In many areas including engine components Low Cycle Fatigue tests are performed at high to ultra-high temperatures under air or in vacuum.

Catalogs

No catalogs are available for this product.

See all of walterbaiag‘s catalogsRelated Searches

- Test machine

- Test cabinet

- Test stand

- Material testing machine

- PC-controllable testing machine

- Compression test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Precision test machine

- Research and development test machine

- Electromechanical test machine

- Stainless steel test cabinet

- Environmental test cabinet

- Hydraulic test machine

- Plastic test machine

- Pull testing machine

- Fatigue test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.