Thermomechanical testing machine fatiguemanualbrake

Add to favorites

Compare this product

Characteristics

- Test type

- fatigue

- Operating mode

- manual

- Test material

- brake, for compressors, for pipelines

- Sector

- industrial, for the aeronautical industry

- Technology

- thermomechanical

Description

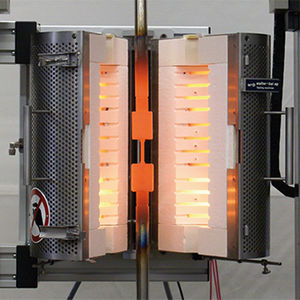

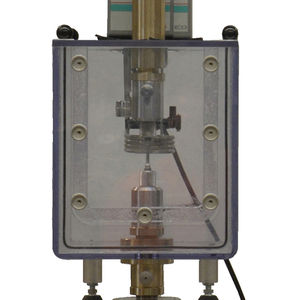

Thermo Mechanical Fatigue (TMF) Systems

Thermomechanical Fatigue is a major cause of component failure in industrial machinery and structures exposed to temperature conditions and mechanical loads that change of over time. TMF affects a range of components, including aircraft and ship engines, components used in gas turbines for power generation and compressors for gas and oil pipelines or train wheels and brakes.

Thermomechanical Fatigue Test Systems are able to replicate the real-world service conditions of these components and simulate the complex effects of simultaneous thermal and mechanical strain. The TMF Test are more sophisticated than the isothermal fatigue LCF Tests due to fluctuation temperatures, commonly higher heating rates and the extraction of the thermal and mechanical strain components from the total measured strain. Mostly TMF tests are conducted under high temperature or vacuum conditions using in-phase, out-of-phase, or a combined mechanical and thermal cycling.

ASTM E2368-04 and ISO 12111 standards as well as EUR22281 Code-of Practice specify the standard practice for strain controlled thermomechanical fatigue testing.

Catalogs

No catalogs are available for this product.

See all of walterbaiag‘s catalogsRelated Searches

- Test machine

- Test cabinet

- Test stand

- Material testing machine

- PC-controllable testing machine

- Compression test machine

- Industrial test machine

- Universal test machine

- Tensile test machine

- Flexure testing machine

- Laboratory test machine

- Precision test machine

- Research and development test machine

- Electromechanical test machine

- Stainless steel test cabinet

- Environmental test cabinet

- Hydraulic test machine

- Plastic test machine

- Pull testing machine

- Fatigue test machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.