Flat belt steelelastomerpulley

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Material

- steel, elastomer

- Product applications

- pulley

- Other characteristics

- maintenance-free, flexible

Description

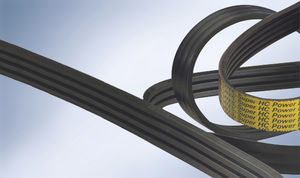

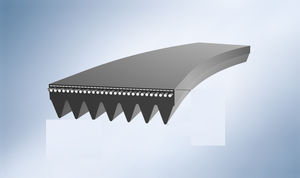

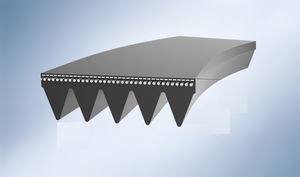

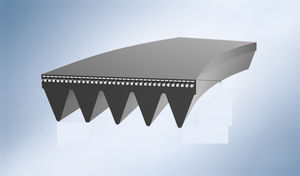

NEOPREN FLAT BELTS

FLEXIBILITY AND ECONOMY

Technical features:

Up to 16 t of lifting force

Belt widths (mm): 30, 50 , 60, 75, 90, 100, 150

Tensile member made of steel

Benefits to you at a glance:

Considerably smaller pulley diameters compared to conventional drive mechanisms

Maintenance-free operation and thus no service or repair costs

Application possible on cylindrical pulleys

Temperature-resistant from -25 °C to +100 °C

High degree of resistance to external influences, abrasion and ageing

Electrically conductive as per ISO 9563

Higher operating speeds with simultaneous reduction of the noise level when compared to chains and steel ropes.

Very low thickness tolerance of +/- 0.13 mm, resulting in even distribution of force in the flat belts while rolling up

Simple installation using clamp connections

Silicone-free design available on request

Walther Flender neoprene flat belts open up new dimensions for driving lift systems. The considerably smaller pulley diameters compared to conventional drive mechanisms allow a system design that saves space and money. Rolling up the flat belt also allows for very low headroom and high effective stroke.

The flat belt is particularly heavy-duty and maintenance-free, i.e. both lubrication and retightening and thus service and repair costs are a thing of the past. The flat belt can also be installed quickly and easily using clamp connections. The flexible design means that the flat belt can be used both as a lifting belt and a drive belt.

The unique elastomer mix has a particularly long service life and, when compared to chains and steel ropes, has a more even and quieter run as well as offering higher speeds.

Catalogs

No catalogs are available for this product.

See all of Walther Flender‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Compact gearbox

- Gear train gearbox

- Shafts coupling

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gear gearbox

- Industrial power transmission belt

- Low-noise gearbox

- Bevel gearbox

- Multi-stage gearbox

- Rubber power transmission belt

- Two-stage gearbox

- Electric motor gearbox

- Torque shaft coupling

- Machine gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.