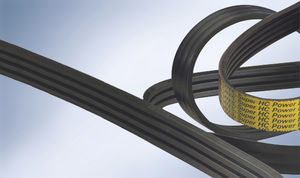

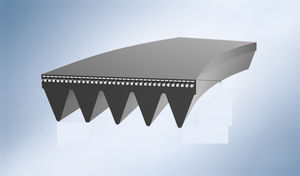

Flat belt polyurethanearamidpulley

Add to favorites

Compare this product

Characteristics

- Type

- flat

- Material

- polyurethane, aramid

- Product applications

- pulley

- Other characteristics

- maintenance-free, flexible, low-noise

Description

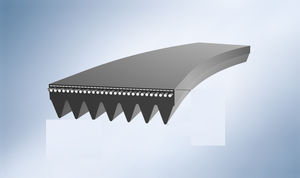

Technical features:

Up to 30 t of lifting force

Belt widths (mm): 25, 50, 75, 100, 150

Steel and aramid tensile member, highly flexible or reinforced

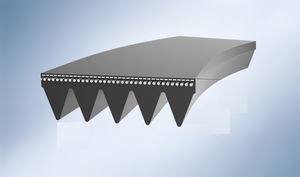

Benefits to you at a glance:

Low-vibration and low-noise run

High degree of strength with low stretching

Designs with FDA and EU food approval on request

Various coatings and carriers available

Considerably smaller pulley diameters compared to conventional drive mechanisms

Maintenance-free operation and thus no service or repair costs

Simple fixing by means of clamping plates or the newly developed FIX-FLAT flat belt fixing system

Walther Flender’s polyurethane flat belts are finite, extruded belts made of high-strength polyurethane. The combination of various types of polyurethane and various tension members, as well as a large selection of coatings and carries, means that the flat belts can be adapted to a wide range of tasks.

The polyurethane flat belts have a particularly gentle, vibration-free run and a high degree of strength with low stretching. The considerably smaller pulley diameters compared to conventional drive mechanisms allow a system design that saves space and money. The flat belt is particularly heavy-duty and maintenance-free, i.e. both lubrication and retightening and thus service and repair costs are a thing of the past.

The flat belt can be installed in the classic manner by means of clamping plates or the newly developed FIX-FLAT solution. FIX-FLAT can be used to fix every flat belt simply, quickly and securely at both belt ends.

Catalogs

No catalogs are available for this product.

See all of Walther Flender‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Gear train gearbox

- Compact gearbox

- Shafts coupling

- Industrial gear reducer

- Transmission gearbox

- Shaft gearbox

- Helical gear gearbox

- Industrial power transmission belt

- Multi-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Bevel gearbox

- Rubber power transmission belt

- Torque shaft coupling

- Low-noise gearbox

- Electric motor gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.