Synchronous belt rubberpositioningindustrial

Add to favorites

Compare this product

Characteristics

- Type

- synchronous

- Material

- rubber

- Product applications

- positioning

- Sector

- industrial

- Other characteristics

- coated

Description

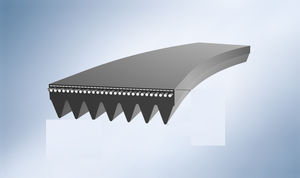

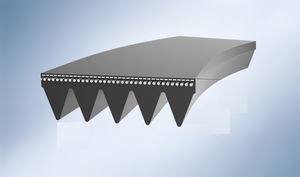

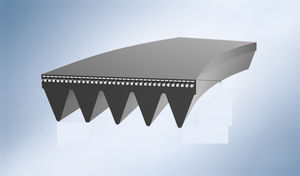

POWERPAINT SYNCHRONOUS BELT

CUSTOMISED FOR USE IN COATING MACHINES

Technical features:

Output range: up to 1000 kW; up to 33 m/s circumferential speed

Divisions: 5, 8, 14

Tensile member made of fibre glass, carbon, aramid

Benefits to you at a glance:

Silicone-free and coating-compatible in accordance with Gates manufacturer`s declaration (11.01.2017) and Gates test method arrangement TM 013 following the VW test specification 03.10.7

Developed especially for coating machines

No lubrication necessary

High power transfer and favourable voltage distribution

Good flexural properties and tensile strength

High positioning precision

Optimum efficiency

The silicone-free and coating-compatible synchronous belt PowerPainTTM (see Gates manufacturer`s declaration (11.01.2017) / Gates test method arrangement TM 013 following the VW test specification 03.10.7) was developed especially for use in coating systems in which freshly coated products must not become contaminated, making it perfect for use in both the automobile industry and the manufacture of household appliances. Extremely carefully executed production steps, perfected material technology and strict quality control of the drive belts before dispatch ensure that the PowerPainTTM synchronous belt passes the demanding tests of the automobile industry.

The silicone-free drive belt will also impress you due to its high positioning precision, optimum efficiency and extremely good flexural properties. The favourable load distribution of the curved tooth system ensures a high degree of power transfer. The PowerPainTTM synchronous belt works problem-free on fixed axial spacing, without elongation and with a long service life.

Catalogs

No catalogs are available for this product.

See all of Walther Flender‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Compact gearbox

- Gear train gearbox

- Shafts coupling

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gear gearbox

- Industrial power transmission belt

- Low-noise gearbox

- Bevel gearbox

- Multi-stage gearbox

- Rubber power transmission belt

- Two-stage gearbox

- Electric motor gearbox

- Torque shaft coupling

- Machine gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.