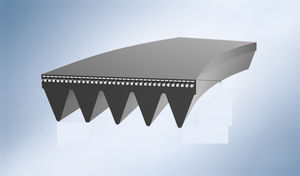

Timing belt T seriespolyurethanesteelpulley

Add to favorites

Compare this product

Characteristics

- Type

- timing

- Material

- polyurethane, steel

- Product applications

- pulley, positioning, food

- Sector

- industrial

- Other characteristics

- metric, abrasion-resistant, wide

Description

FINITE DESIGNS OF POLYURETHANE TIMING BELTS (SOLD BY LENGTH)

IDEAL FOR LINEAR AND LIFT DRIVES

Technical features:

Performance range: circumferential forces of over 25,600 N

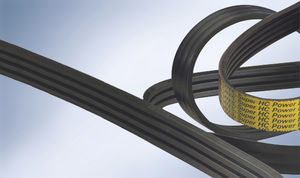

Divisions: T5/T10/T20/AT5/AT10/AT20, wide belt

Tensile member made of steel or aramid

Benefits to you at a glance:

Resistant to lubricants, moisture and chemicals

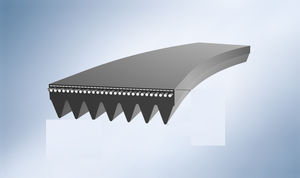

High degree of protection against abrasion due to fabric sheathing

FDA & EU food approval

High rotation speeds and belt speeds

High efficiency

Low belt tension and bearing stress

High positioning precision

Maintenance-free

Long service life

Polyurethane timing belts have a high degree of resistance to lubricants, moisture and chemicals, and are particularly resistant to abrasion thanks to their special fabric sheathing. For this reason, the Walther Flender polyurethane timing belts conform to standards such as FDA and EU food approval.

In addition to infinite drive belts, Walther Flender can offer you the abrasion-resistant polyurethane timing belts in a finite version sold by length in standard, metric and HTD divisions that can be cut to the desired quantity.

The Walther Flender polyurethane timing belts are particularly suitable for use in the food industry, bottling and packing, nutrition and luxury foods, cleanroom technology and medical technology.

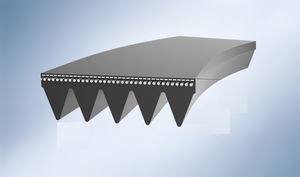

An optimum belt selection can never be made across the board; it must be based on the individual requirements of the application in question. If a specific drive belt that is adapted perfectly to the timing belt pulley is selected, the efficiency of both the timing belt drive and the entire drive train is improved.

Catalogs

No catalogs are available for this product.

See all of Walther Flender‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Power transmission belt

- Flexible shaft coupling

- Compact gearbox

- Gear train gearbox

- Shafts coupling

- Shaft gearbox

- Transmission gearbox

- Industrial gear reducer

- Helical gear gearbox

- Industrial power transmission belt

- Low-noise gearbox

- Bevel gearbox

- Multi-stage gearbox

- Rubber power transmission belt

- Two-stage gearbox

- Electric motor gearbox

- Torque shaft coupling

- Machine gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.