- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

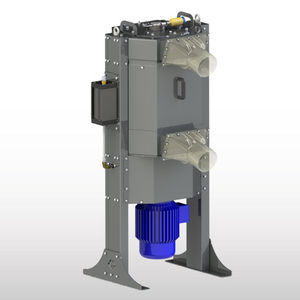

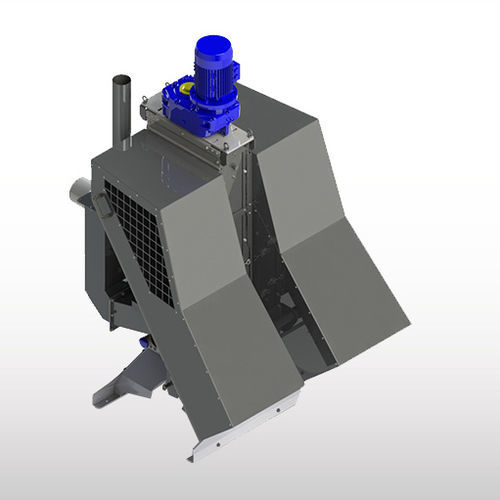

Rotary separator SEPCOM seriesgravitysludgefor solids

Add to favorites

Compare this product

Characteristics

- Technology

- rotary, gravity

- Separated substance

- sludge, for solids

- Application domain

- process, for wastewater treatment

- Other characteristics

- self-cleaning, vertical, high-performance

- Flow

20 m³/h, 45 m³/h

(706.293 ft³/h, 1,589.16 ft³/h)- Length

1,140 mm, 1,690 mm, 1,890 mm

(45 in, 67 in, 74 in)- Width

945 mm, 1,320 mm, 1,500 mm

(37 in, 52 in, 59 in)- Filtration size

15 µm

- Weight

450 kg, 500 kg, 650 kg

(992.08 lb, 1,102.31 lb, 1,433 lb)

Description

SEPCOM Vertical is an innovative screw press solids-liquid separator. Thanks to its special features, vertical work position and a twin-screw design, a variety of materials from biogas plants, industrial processes, as well as slurry from livestock breeding can be treated.

Due to the particular design of the SINT engineering polymer screws, various materials can be easily handled. The special shape of the screen chamber facilitates self-cleaning.

The SEPCOM 0150V is a screw press solids-liquid.

The machine consists of:

- an inlet module

- a separation and conveying module

- a compacting module

The feeding section is provided with a compensator tank and overflow outlet. It is designed to enable the material to directly flow into the separation module. The inlet is positioned at the bottom side of the machine.

The separation and conveying section consists of two vertical contra-rotating conveyor screws inside a screen, which lets the liquid phase pass while the conveyor screws lift the solid phase up into the compacting module.

The compacting module consists of a counter-pressure diaphragm that compacts the solid material, which is then discharged through two special chutes.

SEPCOM Vertical is a solids-liquid separating machine including two vertical screws manufactured from SINT engineering polymer. The special design of the machine ensures that there is no clogging and no loss of the solids plug during operation.

VIDEO

Catalogs

No catalogs are available for this product.

See all of WAMGROUP S.p.A‘s catalogsRelated Searches

- Filter with cartridge

- Solid classifier

- Centrifugal classifier

- Stainless steel separator filter

- Liquids separator

- Filter housing

- Filtration system

- Cartridge filter housing

- Panel pre-filter

- Process classifier

- Compact separator filter

- Gravity classifier

- Metal filter housing

- Compressed air separator filter

- Classifier for the recycling industry

- Stainless steel filter housing

- Bag filter

- Easy cleaning pre-filter

- Self-backwashing filter

- Steel separator filter

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.