- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Powder micro-dispenser MBH series granulesvolumetricfor the food industry

Add to favorites

Compare this product

Characteristics

- Product

- powder, granules

- Type

- volumetric

- Applications

- for the food industry

- Other characteristics

- continuous, ATEX, batch

Description

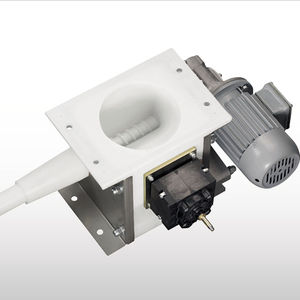

MBH is the most versatile and economic solution for high efficiency micro-batch feeding. It is available in 3 different versions (standard in 316 SS, with SINT™ engineering polymer chamber and feeder pipe and a version for Food applications with ATEX and EC 1935/2004 certification).

The MBH Micro-batch Feeder for continuous volumetric feeding of powdery or granular

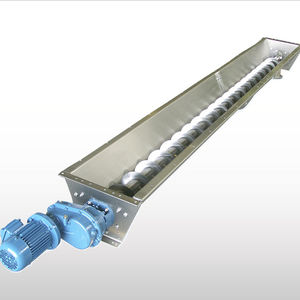

materials consists of a body entirely manufactured from 316 stainless steel or SINT™ engineering polymer, a horizontally mounted rotating blending tool, a feeder screw beneath the blending tool, a feeder pipe enclosing the protruding feeder screw, as well as a drive unit.

Function

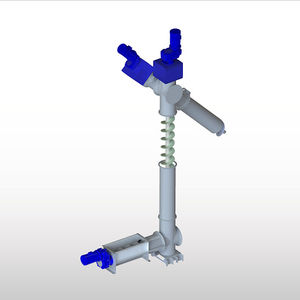

Featuring multiple patent pending components, MBH is an high efficiency Micro-batch Feeder for continuous volumetric feeding of powdery or granular materials. High performance MBH Micro-batch Feeders have been successfully operating in the following bulk handling industries: food, building, plastics, chemicals, packaging and environmental technology.

• Interchangeablity of standard components and accessories within the WAM® feeder range

• Easy removal of parts in contact with the product

• Lubrication-free gear reduction unit completely detachable from body Discharge valve to intercept material flow

• Seamless Internal Chamber Design with Transparent Inspection Hatch

• Quick Coupling Metering Tools (2 extra feeder tools included as standard)

• Minimum residue

• Low energy consumption

• High metering accuracy

• Easy cleaning due to ergonomic design

Options

• with SINT™ engineering polymer chamber and feeder pipe

VIDEO

Catalogs

No catalogs are available for this product.

See all of WAMGROUP S.p.A‘s catalogsRelated Searches

- WAMGROUP dynamic mixer

- WAMGROUP batch mixer

- Grinding mill

- WAMGROUP liquid mixer

- WAMGROUP mixer for the food industry

- WAMGROUP solid mixer

- WAMGROUP stainless steel mixer

- Agitator for the chemical industry

- Horizontal grinding mill

- In-line mixer

- Food lump breaker

- WAMGROUP powder mixer

- Solid/liquid homogenizer

- WAMGROUP horizontal mixer

- Agitator for the pharmaceutical industry

- Rotor lump breaker

- Construction agitator

- Paddle blender

- Homogenizer for the cosmetics industry

- Roller grinding mill

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.