- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

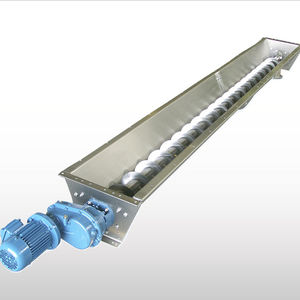

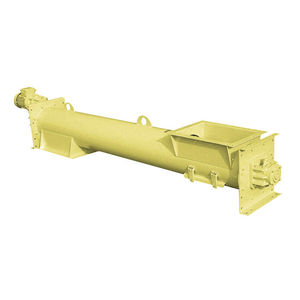

Screw conveyor TP-TE horizontaltroughtubular

Add to favorites

Compare this product

Characteristics

- Technology

- screw

- Form

- horizontal, trough, tubular

- Function

- transport, loading, unloading

- Drive mechanism

- electric drive

- Transported product

- cement

- Applications

- for heavy loads, for heavy-duty applications

- Sector

- construction, for the mining industry, for the metallurgical industry

Description

TP / TE Tubular Screw Conveyors are used for both batch and continuous operation in applications where durability and easy replacement of those conveyor components that are subject to wear are among the main requirements.

Typically this screw conveyor type finds application in minerals processing, glass processing, foundries, cement mills, gypsum and lime production, as well as in the mining industry.

TP and TE-type Screw Conveyors are designed for medium heavy-duty (TP) and extra heavy-duty (TE) applications. Manufactured from carbon steel with a suitable surface finishing, they are made up from a tubular trough equipped with at least one inlet and outlet spout, an end plate flanged on each tube end, helicoid screw flighting welded on a centre pipe with coupling bush (TP) or flanged coupling (TE) at each end, two end bearing assemblies complete with adjustable shaft seal, and a number of intermediate hanger bearings depending on the overall length of the screw conveyor. TP / TE Tubular Screw Conveyors are equipped with a gear motor and in most cases with an additional power transmission suitable for the application.

TP Screw Conveyors are used in the same sectors as the TU-type if the throughput rate reached by the latter is insufficient to meet the needs of the application (feeders or conveyors for cement, fly-ash, filler dust, silica fume in concrete production, hot and cold filler dust in asphalt production, plasters, sand, cement, additives in processing of premixed building materials, calcium carbonate, soda, sand, in glass processing, sand and bentonite in foundries, and in many other industrial sectors).

Catalogs

No catalogs are available for this product.

See all of WAMGROUP S.p.A‘s catalogsRelated Searches

- WAMGROUP conveyor

- WAMGROUP dynamic mixer

- WAMGROUP transport conveyor

- WAMGROUP horizontal conveyor

- WAMGROUP conveyor for the food industry

- WAMGROUP liquid mixer

- WAMGROUP mixer for the food industry

- WAMGROUP solid mixer

- WAMGROUP electric drive conveyor

- WAMGROUP stainless steel mixer

- WAMGROUP inclined conveyor

- In-line mixer

- WAMGROUP powder mixer

- WAMGROUP handling conveyor

- Solid/liquid homogenizer

- WAMGROUP horizontal mixer

- WAMGROUP modular conveyor

- WAMGROUP screw conveyor

- Construction agitator

- Paddle blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.