- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

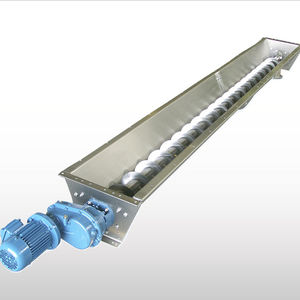

Screw conveyor CAhorizontaltroughtransport

Add to favorites

Compare this product

Characteristics

- Technology

- screw

- Form

- horizontal, trough

- Function

- transport

- Construction

- modular

- Drive mechanism

- electric drive

- Transported product

- for granulates, for powders, for wood, cement, powder

- Applications

- for heavy-duty applications, light-duty

- Sector

- for the food industry, for the mining industry

Description

The modular CA Trough Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. They are widely used all over the world in industries such as pet food, plastics processing, soap, washing powder and detergent processing, animal feed milling, wood processing, chemicals, environmental technology, cement, lime and gypsum processing, as well as mining.

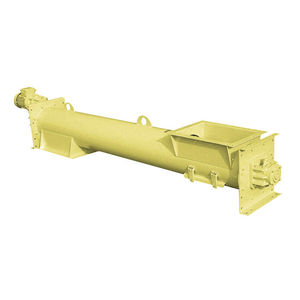

The modular CA Trough Screw Conveyor system is highly versatile offering numerous solutions for conveying powdery or granular materials. CA Screw Conveyors are manufactured from carbon steel with suitable surface finishing. They are made up of a U or V-shaped trough equipped with at least one outlet spout, an end plate at each trough end, helicoid screw flighting welded on a centre pipe with coupling bush at each end, two end bearing assemblies complete with shaft seal, a certain number of intermediate hanger bearings depending on the overall length of the screw conveyor, and bolted trough cover sections. Furthermore, CA Trough Screw Conveyors are equipped with a gear motor appropriate for the application.

Depending on the material to be handled, CA Trough Screw Conveyors come in a light, medium-heavy, or extra heavy-duty design.

All types are available with ATEX, Zone 22 certification.

Function

The light-duty version, CA_L, is mainly used to convey powders or granular materials in the production of pet food, in the plastics industry, as well as in soap, washing powder and detergent processing. The medium heavy-duty version, CA_P, is mainly used in animal feed milling, in wood processing, in the chemica.

VIDEO

Catalogs

Related Searches

- WAMGROUP conveyor

- WAMGROUP dynamic mixer

- WAMGROUP transport conveyor

- WAMGROUP horizontal conveyor

- WAMGROUP conveyor for the food industry

- WAMGROUP liquid mixer

- WAMGROUP mixer for the food industry

- WAMGROUP solid mixer

- WAMGROUP electric drive conveyor

- WAMGROUP stainless steel mixer

- WAMGROUP inclined conveyor

- In-line mixer

- WAMGROUP powder mixer

- WAMGROUP handling conveyor

- Solid/liquid homogenizer

- WAMGROUP horizontal mixer

- WAMGROUP modular conveyor

- WAMGROUP screw conveyor

- Construction agitator

- Paddle blender

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.