- Packing - Handling - Logistics

- Conveying

- Screw conveyor

- WAMGROUP S.p.A

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

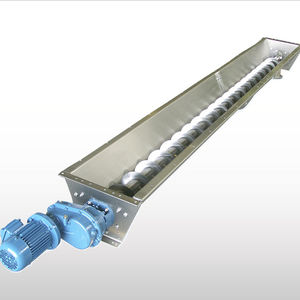

Shaftless screw conveyor SSChorizontalspiraltrough

Add to favorites

Compare this product

Characteristics

- Technology

- shaftless screw

- Form

- horizontal, spiral, trough

- Function

- transport

- Construction

- modular

- Transported product

- food, for waste, sludge, solids

- Applications

- for heavy-duty applications

- Sector

- for the food industry

- Other characteristics

- stainless steel

Description

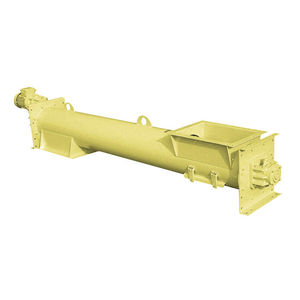

SSC Shaftless Screw or Spiral Conveyor are an alternative concept to traditional shafted screw conveyors. Material is conveyed by an extra heavy-duty shaftless screw that slides on a wear-resistant, low-friction liner inside the conveyor trough housing.

The longitudinally divided U-section troughs are manufactured from carbon or 304 L / 316 L stainless steel, including an appropriate surface treatment. Fabricated parts, except the ultra heavy-duty screw, are of the medium heavy-duty type. The cross section of the lower part of the trough is slightly wider than the side channels to allow for the liner to be inserted in the lower trough part. After complete assembly of the trough the liner is kept in place by the upper trough side channels. At one trough end there is a vertical or flush-type outlet. At the drive end the screw conveyor is equipped with an end plate holding the end bearing assembly with flanged shaft coupling to the spiral. The installed drive unit suits the application.

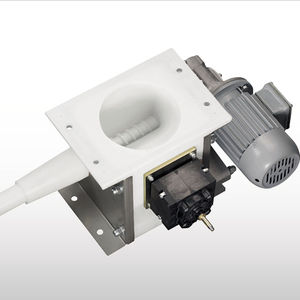

SSC can be loaded from above into the open trough (standard), or through an inlet spout included in a bolted trough cover (option), or from the side through a special side inlet in the loading zone of the trough (option).

Shaftless screws (spirals) offer a larger volume capacity and the possibility of handling particularly difficult materials like those that tend to become tangled up or those that present highly variable particle size. Material properties, oversize thickness, as well as a special manufacturing process make the spiral highly resistant and extremely durable. Due to the absence of intermediate bearings, obstacle-free material handling is guaranteed.

VIDEO

Catalogs

Related Searches

- WAMGROUP conveyor

- WAMGROUP transport conveyor

- WAMGROUP horizontal conveyor

- WAMGROUP conveyor for the food industry

- Feeder

- WAMGROUP electric drive conveyor

- WAMGROUP inclined conveyor

- Drag chain conveyor

- Relief valve

- WAMGROUP industrial vibrator

- WAMGROUP food conveyor

- WAMGROUP stainless steel conveyor

- WAMGROUP handling conveyor

- WAMGROUP modular conveyor

- WAMGROUP bulk material conveyor

- WAMGROUP screw conveyor

- Loading and unloading system

- WAMGROUP feeder conveyor

- WAMGROUP unloading conveyor

- Conveyor for the pharmaceutical industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.