- Packing - Handling - Logistics

- Conveying

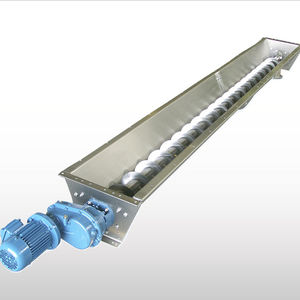

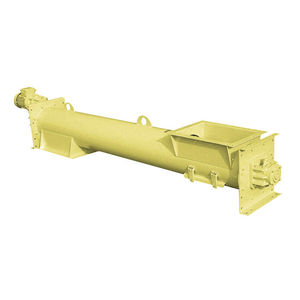

- Screw conveyor

- WAMGROUP S.p.A

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Spiral conveyor VEshaftless screwverticalelectric drive

Add to favorites

Compare this product

Characteristics

- Technology

- shaftless screw

- Form

- vertical, spiral

- Drive mechanism

- electric drive

- Sector

- for the food industry, construction

- Transported product

- for bulk materials, food, for granulates, for powders, for waste, sludge, for precast concrete

- Other characteristics

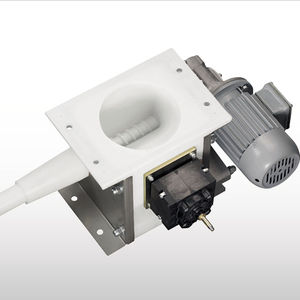

- for transport, modular, for heavy-duty applications, tubular, stainless steel, trough, loading, unloading, feeder

Description

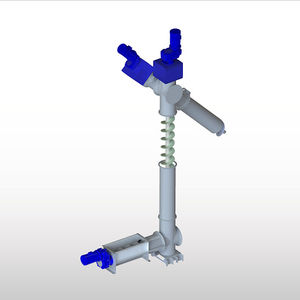

VE Vertical Screw Lift Systems are the most economical and space saving solution for transferring powders or granular materials from a lower to a higher level. The bulk material withdrawn from a silo, hopper, conveying or feeding device may be discharged by the vertical screw into a weigh hopper, into one or more bins or silos, or into another conveyor or conveying system.

VE Vertical Screw Lift Systems excel through high volumetric efficiency and excellent mechanical features.

The VE Vertical Screw Lift System consists of a Horizontal Screw Feeder and a Vertical Screw Conveyor.

The Horizontal Screw Feeder feeding material from a silo or hopper or conveying it fed by an upstream feeding device, consists of a U-shaped or tubular carbon steel trough with appropriate surface finishing. The outlet zone of the horizontal screw feeder consists of a short tubular section tangentially flanged at a right angle on the bottom section of the Vertical Screw Conveyor. A flange is welded at each end of the Horizontal Screw Feeder. The trough or tube contains a rotating screw with coupling bushes at each end connected with the shafts of the two end bearing assemblies. The Horizontal Screw Feeder is equipped with one or more intermediate hanger bearings should its overall length require them. Furthermore, the Horizontal Screw Feeder is equipped with a drive unit suitable for the application.

VIDEO

Related Searches

- WAMGROUP conveyor

- WAMGROUP conveyor for the food industry

- Feeder

- WAMGROUP electric drive conveyor

- Drag chain conveyor

- Relief valve

- WAMGROUP industrial vibrator

- WAMGROUP food conveyor

- WAMGROUP stainless steel conveyor

- WAMGROUP handling conveyor

- WAMGROUP modular conveyor

- WAMGROUP bulk material conveyor

- WAMGROUP screw conveyor

- Loading and unloading system

- WAMGROUP unloading conveyor

- Conveyor for the pharmaceutical industry

- Loading conveyor

- Pilot-operated relief valve

- Compact conveyor

- Pneumatic vibrator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.