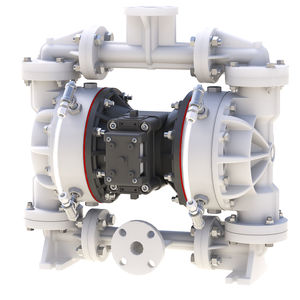

Double-diaphragm pump S20 waterfor chemicalsair

Add to favorites

Compare this product

Characteristics

- Technology

- double-diaphragm

- Fluid

- water, for chemicals, air

- Mobility

- stationary

- Domain

- industrial

- Applications

- discharge, handling, distribution, service, suction, recovery, replacement

- Material

- PTFE, polypropylene, PVDF

- Fluid specification

- for hazardous fluids

- Other characteristics

- non-metal

- Flow

Min.: 0 us gal/min

(0 l/min)Max.: 160 us gal/min

(605.66589 l/min)- Pressure

Min.: 0 bar

(0 psi)Max.: 7 bar

(101.526 psi)- Head

Min.: 0 m

(0'00" )Max.: 70 m

(229'07" )- Width

381 mm

(15 in)- Height

819 mm

(32.24 in)- Weight

43 kg, 45 kg, 59 kg

(94.8 lb, 99.21 lb, 130.07 lb)

Description

For more than 55 years, manufacturers across multiple industries that involve hazardous materials have trusted SANDPIPER to protect people, equipment, the environment and the material being pumped.

The SANDPIPER S20 Non-Metallic 2" AODD Pump provides unsurpassed fluid containment in the event a diaphragm is breached.

Typical Pump Versus Containment-Duty Pump

In a typical AODD pump, when the pumping diaphragm is breached, the fluid enters the air distribution system and escapes into the environment through the muffler, requiring immediate service.

In a containment-duty pump, when the pumping diaphragm is breached, the fluid enters the containment chamber and visual indicator sight tubes, alerting the user. The fluid is fully contained so the pump can continue running until the operation is complete or maintenance can be scheduled.

This leak-free pump is designed to be driven by compressed air or nitrogen.

Why Use Containment-Duty Pumps?

Environmental concerns: When fluids (like those listed below) escape to the environment, significant time and effort is required on clean up and material recovery. Additionally, the costs of downtime, lost production, manpower, equipment replacement, disposal fees and fines can be excessive. Preventing leaks when handling these substances provides a more efficient operation and avoids the damaging effects of environmental and human exposure to these toxic fluids.

Paints, inks and coatings

Adhesives and resins

Chemicals and petrochemicals

Oils and hydrocarbons

Acids, caustics and corrosives

Plastics and polymers

Contaminated water and wastewater

Pesticides and herbicides

Fertilizers

Catalogs

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Compact pump

- Suction pump

- Lubricating oil pump

- Submersible pump

- Diaphragm pump

- Air-driven pump

- Flow pump

- Mechanically-actuated pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.