- Robotics - Automation - Industrial IT

- Automation

- Process indicator controller

- Watlow Electric Manufacturing Company

Process indicator controller Eurotherm piccolo™ P304iuniversalpowerpressure

Add to favorites

Compare this product

Characteristics

- Measured value

- universal, pressure, process, power

- Display

- with LED display

- Other characteristics

- precision

Description

Both the piccolo™ P304i Melt Pressure indicator and P304c controller have a 50ms sample rate to give the fast-acting control and alarm functionality required in the plastics industry. The P304c controller provides outstanding control performance in an affordable package for a wide variety of pressure sensors.

Input/output flexibility

A strain gauge or process linear input is standard with an optional strain gauge input for differential pressure control, or a universal input for remote setpoint. Up to two opto-isolated DC linear outputs are available for control or retransmission along with one standard logic input for alarm reset/acknowledge or zero calibration of sensor. An additional four logic inputs may be selected for remote activation of functions like auto/manual mode selection and increase/ decrease of power output.

The Display

A custom, dual-line 5-digit display provides a complete view of the process while a horizontal bar graph gives clear visual indication of the process input. The status of alarms, outputs, active setpoint and engineering units are represented with clear beacons on the front of the unit.

Configuration

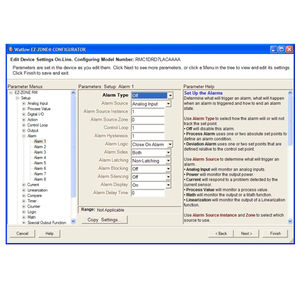

The P304 is fully software configurable using iTools PC configuration and parameter monitoring. iTools provides the ability to edit, store and ‘clone’ complete controller configurations as well as data logging and process monitoring capability.

Features:

Easy to integrate and use in new and legacy applications

Fast-acting alarms to protect against overpressure

Responsive, precision PID control with overshoot inhibit

Easy, effective auto-tune

Universal + strain gauge inputs

Second input for differential pressure indication/ control

Catalogs

No catalogs are available for this product.

See all of Watlow Electric Manufacturing Company‘s catalogsExhibitions

Meet this supplier at the following exhibition(s):

MEORGA Bochum 2024

30-30 Oct 2024 Stadionring 20, 44791 Bochum, Deutschland (Germany)

More information

Other Watlow Electric Manufacturing Company products

Controllers

Related Searches

- Digital master module

- I O module

- Digital I O module

- Watlow digital temperature control

- Watlow temperature controller

- HMI with touch screen

- Communication gateway

- Programmable logic controller

- Watlow digital temperature controller

- FOUNDATION Fieldbus gateway

- Ethernet gateway

- LCD HMI

- Remote master module

- PID temperature control

- Panel-mount HMI

- CANopen PLC

- DIN rail gateway

- Fieldbus programmable logic controller

- PID temperature control unit

- Communication module

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.