- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

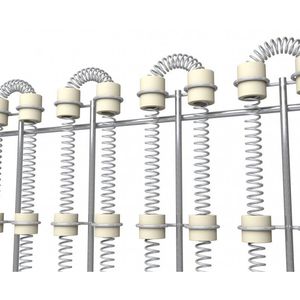

110 V cartridge heater 220-240 Vstainless steelIncoloy

Add to favorites

Compare this product

Characteristics

- Voltage

- 220-240 V, 110 V

- Material

- stainless steel, Incoloy, titanium

Description

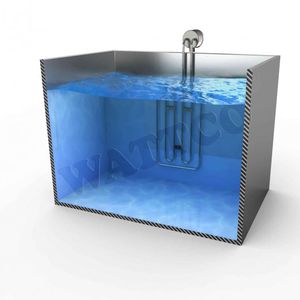

Cartridge heaters can be considered “component heaters” that are used to generate heat in many different applications. These process heaters are primarily used in mold and fit snug inside a cavity and helps heat solids by reaching high temperatures. Cartridge heaters have the versatility of being able to carry thermocouple inside to help control temperatures of the heater more accurately. Various diameters allow for it to be used in any cavity and can be custom designed with any cold section. Lead wires extend from the end to your control panels. Cartridge heaters are used as a water heater element and in a wide variety of applications. Some of these uses include bag sealing applications, hydraulic oil applications, motor oil applications, gearboxes, water heating applications as well as laboratory and food equipment. Sheaths can reach extreme temperatures as cartridge heaters can be designed with higher watt densities. High watt density cartridge heaters can also have different types of lead wire connections. For more mechanical processes, stainless steel braided leads are used against mechanical stress. BX cabling can be used for added protection, though it reduces the lead wire flexibility. Terminal pins are also available on all models. Cartridge heaters from Wattco are made of a swaged construction that consists in a high-grade nickel chromium resistance wire wound around a high-quality MgO core that is centered in a stainless steel casing. Cartridge heaters are used for heating metal parts and can also be fitted with threaded bushings for liquid heating for certain applications.

Catalogs

No catalogs are available for this product.

See all of WATTCO‘s catalogsRelated Searches

- Resistance heater

- WATTCO heater

- Gas heater

- Air heater

- WATTCO electric heater

- Immersion heater

- WATTCO liquid heater

- Tubular resistance heater

- Cartridge heater

- Convection heater

- Circulation heater

- Flat resistance heater

- Stainless steel heater

- Band heater

- Flexible resistance heater

- Industrial resistance heater

- Duct heater

- Preheater module

- Stainless steel resistance heater

- Water heater

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.