- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Temperature controller without display programmableheatingpanel-mount

Add to favorites

Compare this product

Characteristics

- Display

- without display

- Type

- programmable

- Use

- heating

- Other characteristics

- panel-mount

Description

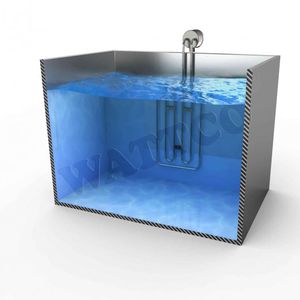

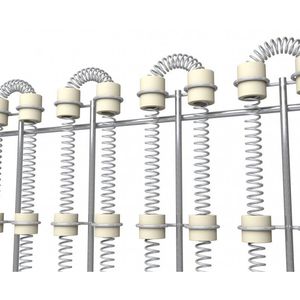

There are a number of outputs that are used with temperature and process controllers, some of the common ones include, solid state relay drivers, linear along outputs, relay outputs, and triac. The relay output commonly is a single pot double throw relay which comes with a DC voltage coil.

The controller works by isolating the contacts using the energy added to the relay coil. This lets the contacts make use of the external voltage source, which ultimately powers the larger heating contactor. The contacts used in the process are designed to control the output in addition to handling the process timing and proper execution.

Temperature and process controllers are an integral part of the workings of a number of industries. The best industrial functions need proper maintenance of process schedules and temperature levels both of which are controlled by these controllers.

Food and Beverage Industry Packaging

The packaging industry is heavily dependent on temperature maintenance for proper functioning. The machinery used in packaging which includes hot melt functions, glue applicators, seal bars, label applicators, and shrink wrap tunnels are designed to operate at a certain temperature and to process for a set length of time. Both of these processes are regulated by temperature and process controls. Process controllers control the process time limit, while temperature controllers ensure that the wanted temperature is maintained throughout.

Food and beverage industry

The food and beverage industry is another place where temperature plays a vital role.

Catalogs

No catalogs are available for this product.

See all of WATTCO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.