- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Centrifugal pumping unit waterwith electric motorself-priming

Add to favorites

Compare this product

Characteristics

- Technology

- centrifugal

- Fluid

- water

- Operation

- with electric motor

- Priming

- self-priming

- Mobility

- stationary

- Domain

- industrial

- Applications

- transfer, process, control

- Other characteristics

- compact, standard, small

- Flow

Min.: 5 us gal/min

(18.92706 l/min)Max.: 100,000 us gal/min

(378,541.1784 l/min)- Pressure

Min.: 0 bar

(0 psi)Max.: 250 bar

(3,625.943 psi)- Fluid temperature

Min.: -40 °C

(-40 °F)Max.: 200 °C

(392 °F)

Description

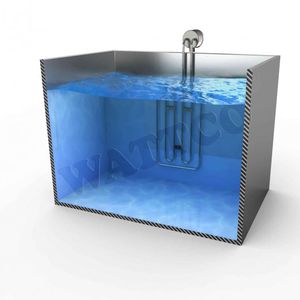

Being a solution that can be used in diverse applications in many industries, the Integral Pumping Module (IPM) is different as it functions at a high level of efficiency and at the same time it is small, compact, and versatile.

The IPM brings together all the necessary pieces that are essential for pumping and fluid management in one compact module, thereby, providing the customer with the easiest and the most efficient way of fluid transfer and pressure control.

By nature, it is a product designed to be very simple during installation, a product that will not disappoint in the reliability domain and one, because of lesser maintenance requirements, will be chosen by engineers along with plant operations in their respective fields.

Integral Pumping Module: What is It?

A complete system is a devaluation of the modules that combines the interactions among the valves, pumps, sensors, pipelines, and control systems into one core module.

This versatile ASI is designed to be efficient for the meat packing process and reliability.

In contrast to the older system, which called for distinct machinery pieces and vast pipework, the IPM is a prefabricated solution that can be readily matched with well-established methods or used as a separate standard product.

Essential Modules and Design

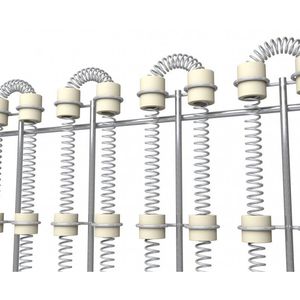

Pump: In the process of transforming chemicals around in the system, the IPM, in essence, becomes the pump of the whole unit, this can be varied (centrifugal, positive displacement, etc.) according to application. These pumps are selected to meet the specific flow rate and pressure requirements of the system.

VIDEO

Catalogs

No catalogs are available for this product.

See all of WATTCO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.