- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Electric pressure booster pump unit centrifugal

Add to favorites

Compare this product

Characteristics

- Motor type

- electric

- Specifications

- centrifugal

- Flow

Max.: 5,000 us gal/min

(18,927.05892 l/min)Min.: 10 us gal/min

(37.85412 l/min)- Pressure

200 psi

Description

In a season when the transportation of products in a liquid state and the handling of pressure have emerged as some of the big problems in several industries, the Booster Pumping Modules have been fast-moving from the list of modern engineering and various infrastructural systems to a top position.

They are a new development that is designed to replace the current ones with several multicolumns charged with the desired amount. They are meant to adjust the pressure of fluids in the pipes, resulting in a more accurate transportation of the aforementioned fluids to the places where they are supposed to be.

This opening section gives details about Booster Pumping Modules involving among others the main features and uses in different applications.

What is a Booster Pumping Module?

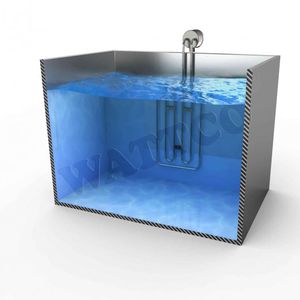

A Booster Pumping Module is a system that pushes the fluid along through the pipeline network employing pumps, controls, and other important components which are physically connected to the pumps.

These electromechanical systems are particularly in demand where the existing head is not enough for the needed flow which might be the case in high-rise buildings, long-distance pipelines, and difficult industrial plants.

Key Components and Design

Pumps: A module is incomplete without a pump, the heart of that module symbolizing one or a few pumps operating together to bring the liquid pressure to a certain point. Among these are centrifugal, positive displacement, or diaphragm pumps, which are selected based on the application’s specific preferences.

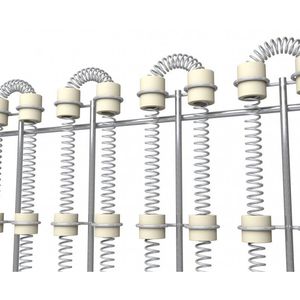

Control System: The control system uses the most up-to-date control technologies such as variable frequency drives (VFDs) and pressure sensors

VIDEO

Catalogs

No catalogs are available for this product.

See all of WATTCO‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.